Benchtop NMR Study on Rubber Content in Various Materials

Benchtop NMR in QC/QA and Product Development Fields

In material industry, the amount of rubber in various materials directly affects the physical and chemical performance parameters of the material.Therefore, the rubber content of various materials is a very key indicator for quality control. In industrial production, to produce rubber for different purposes, it is necessary to measure the rubber content of materials to optimize the process and carry out product quality control, so as to ensure product quality and stabilize product performance. Benchtop NMR can study the rubber content of various materials and can detect the rubber content in various materials quickly, accurately and non-destructively.

Benchtop NMR Test ABS Rubber Content

The heat distortion temperature of heat-resistant ABS resin is generally 90~105℃, and it has good heat resistance, toughness and fluidity. It can be used in the production of automobile doors, inner panels of rear wheel covers, panels, etc. Used in home appliances, such as microwave ovens, rice cookers, hair dryers, etc. The heat resistance of ABS can be improved by reducing rubber content, increasing SAN molecular weight and acrylonitrile content.

Benchtop NMR Test Polypropylene Rubber Content

Adding rubber to polyethylene increases product flexibility and reduces brittleness. Different rubber content directly affects the flexibility of the product. Modified polypropylene with different rubber content has different physical properties and different uses. The ethylene content of impact copolymer products can be as high as 22% (rubber content is greater than 40%). Therefore, in the large-scale production of products, it is very critical to accurately control the rubber content in order to ensure product performance. Low-field nuclear magnetic resonance techniques can be used to rapidly and accurately detect rubber content in impact-resistant polystyrene.

Benchtop NMR Test Rubber content in compound rubber

The amount of rubber in the compound rubber directly affects the physical and chemical properties of the compound rubber, so it is very important to control the amount of rubber. In industrial production, to produce rubber for different purposes, it is necessary to measure the rubber content to optimize the process and carry out product quality control, thereby ensuring product quality and stabilizing product performance.

Benchtop NMR Study Rubber Content in Various Materials

The basic principle of measuring polypropylene with high rubber content by small NMR method: the initial amplitude of the NMR signal is proportional to the number of H nuclei in the sample to be tested, and the decay speed of the signal is related to the group and environment where the H nuclei are located in the sample. In the measurement of high rubber content polypropylene, the NMR signal of the matrix decays very quickly, generally decaying to zero within ten micrometers. The NMR signal decay of rubber packing is much slower, usually the signal can last for tens or hundreds of milliseconds. Therefore, by properly sampling the NMR signal, only the NMR signal of the mineral oil component can be obtained, and thus quantitative measurements can be made. Figure 1 shows the Free Induction Decay (FID) signal detected after a 90-degree pulse.

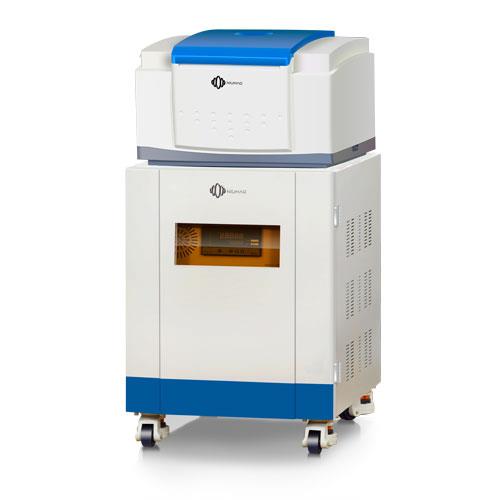

NIUMAG

NIUMAG