Elastomeric Materials – Evaluation of Degradation Process

Application Background

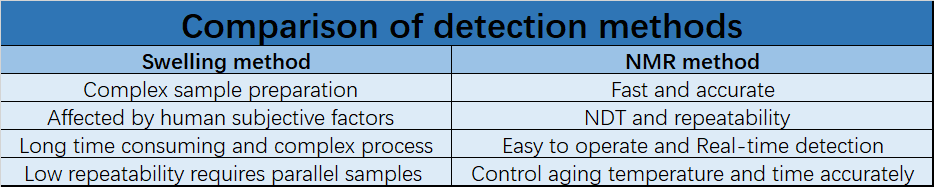

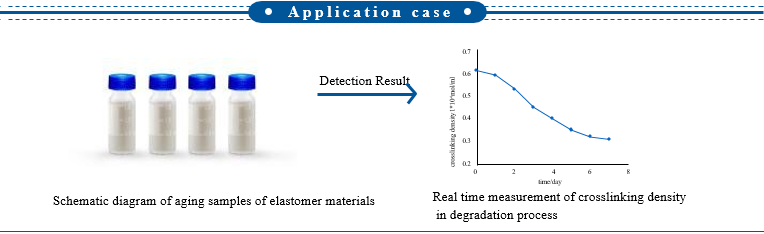

Elastomer materials have a wide application. Affected by the temperature, time, pH and other factors, elastomer materials will degrade and age, which cannot meet the requirement. Therefore, it is necessary to monitor the degradation process of elastomer materials and observe the performance changes. The crosslinking density is an important basis for evaluating the degradation process. The swelling method has low accuracy and is subject to human factors. The NMR method is fast and nondestructive. It can get accurate crosslinking density test results in about one minute. It is very suitable for industrial production to evaluate the rubber degradation process, optimize the process and control the product quality.

Product Application

Sample: Elastomer material

Specifications: Probe size 10mm,sample maximum height 2cm

Note: The sample must not contain ferromagnetic substances

Principle Introduction

Testing principle of crosslinking density of elastomer materials: the crosslinking section has a large degree of binding, small molecular motion characteristics and rapid attenuation; In the process of degradation and aging, the crosslinking density of elastomer materials will decrease. Through technical innovation, NIUMAG has realized the rapid acquisition of short relaxation signals. The cross-linking density test results are accurate. Unknown samples can be tested within 30 seconds to 2 minutes. The test process is fast and nondestructive.

NIUMAG

NIUMAG