La técnica de RMN de campo bajo estudia la evolución de la movilidad de la cera durante la cristalización de la cera

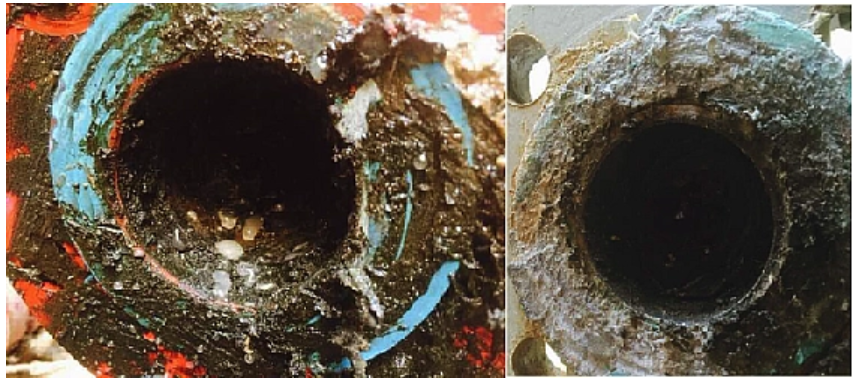

Low temperature crystallization of wax is one of the main problems affecting the fluidity of crude oil during oil recovery. La precipitación de cera ocurre en un ambiente fluido. (QUÉ) a una temperatura inferior a la temperatura de cristalización de la cera. This phenomenon negatively affects flow assurance during crude oil extraction. Continuous flow reduction due to wax gelation and fluid viscosity increase, and wax deposition during pipeline restarts are common problems encountered during crude oil production.

Why do oil wells form wax?

Paraffins are constituents of crude oil, consisting of normal, isomeric or naphthenic hydrocarbons, usually with carbon chains of C20 and C100 or even higher. The fundamental reason why oil wells deposit wax in the production process is that the crude oil produced by oil wells contains wax. There are two processes in oil well wax deposition. Primero, the wax is precipitated from the crude oil, and then it accumulates and adheres to the pipe wall. The wax originally dissolved in crude oil is condensed out during the mining process because the solubility of crude oil to wax decreases. When the composition, temperature and pressure of the crude oil change, so that the solubility of the crude oil decreases, a part of the wax is precipitated from the crude oil.

How harmful is oil well wax precipitation?

Oil well wax precipitation not only causes a lot of daily management wax removal and well workover wax removal, but also has a serious impact on oil well production and even oilfield development. Oil well wax precipitation brings a lot of work to daily management and increases the possibility and probability of downhole accidents. Wax precipitation will increase oil flow resistance and reduce oil well productivity. Current wax removal measures will increase development costs and affect oilfield development. economic effect.

What are the influencing factors of oil well wax precipitation?

1. Composition and temperature of crude oil

Under the same temperature conditions, the solubility of light oil to wax is greater than that of heavy oil. The lighter components contained in crude oil, the lower the crystallization temperature of wax, eso es, wax is not easy to precipitate, and wax in dissolved state is maintained. more quantity. The amount of wax dissolved by any kind of petroleum decreases with decreasing temperature.

Por lo tanto, part of the amount of wax dissolved at high temperature will be condensed out when the temperature is lowered. Under the same wax content, the wax crystallization temperature of heavy oil is higher than that of light oil, and it can be seen that the oil with less light components can easily condense out the wax.

2. Pressure and Dissolved Gas

Under the condition that the pressure is higher than the saturation pressure, the crude oil will not degas when the pressure is decreased, and the initial crystallization temperature of the wax decreases with the decrease of the pressure. Under the condition of pressure and saturation pressure, since the gas in the oil is continuously separated when the pressure is lowered, the dissolving ability of the wax is reduced, so the initial crystallization temperature increases. high.

This is because the light component gas methane: ethane is separated in the initial stage, and the heavy component gas such as butane is separated in the later stage. Además, when the dissolved gas is separated from the oil, it also expands and absorbs heat, which reduces the temperature of the oil flow and is conducive to the precipitation of wax crystals.

3. Gum and Asphaltenes in Crude Oil

The experimental results show that the crystallization temperature can be decreased with the increase of colloidal content in petroleum. Because colloid is a surface active substance, it can be adsorbed on the surface of paraffin crystal to prevent the development of crystallization. Bitumen is a further polymer of colloid, which is insoluble in oil, but dispersed in oil as tiny particles, which have a dispersing effect on paraffin crystals. Sin embargo, when the wax deposited on the pipe wall contains colloid and asphaltene, it will form a hard wax, which is not easy to be washed away by the oil flow.

4. Mechanical Impurities and Water in Crude Oil

The fine particles and mechanical impurities in the oil will become the crystallization core of the paraffin precipitation, which makes the wax crystals easy to aggregate and grow, and accelerates the process of wax deposition. When the water content in the oil increases, the temperature drop of the liquid flow can be reduced because the thermal solubility of the water is greater than that of the oil. Además, due to the increase of water content, it is easy to form a continuous water film on the oil pipe wall, so that the wax is not easy to deposit on the pipe wall. Por lo tanto, as the water cut of the oil well increases, the degree of wax deposition decreases. Sin embargo, when the water content is low, the wax precipitation is more serious, because the salts in the water are precipitated and deposited on the tube wall, which is conducive to the aggregation of wax crystals.

5. Flow velocity, surface roughness of the tube

The actual production of oil wells shows that the wax precipitation in high-yield wells is not as serious as that in low-yield wells. Because of the high pressure of high-production wells, less degassing, low initial crystallization temperature, and high liquid flow velocity, heat loss in the wellbore is small, oil flow temperature is high, and wax is not easy to precipitate. Even if the wax product is precipitated, it will be taken away by the high-speed oil flow and not easily deposited on the pipe wall. If the tube wall is rough, wax crystals are easy to adhere to it to form wax formation, otherwise it is not easy to wax formation. The stronger the hydrophilicity of the surface of the tube wall, the less likely it is to form wax, on the contrary, it is easy to form wax.

What are the low-field NMR techniques used in the study of wax crystallization process?

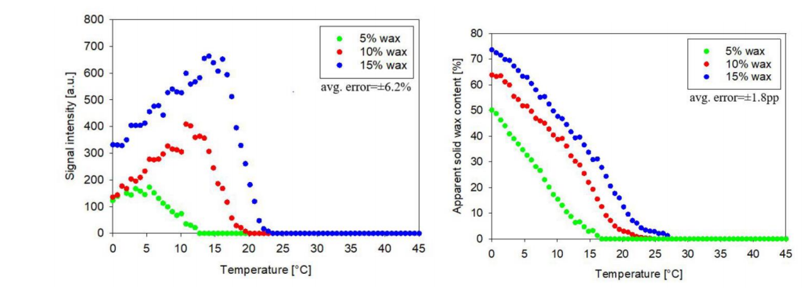

Doctor Batsberg Pedersen et al. first introduced low-field NMR to analyze wax precipitation in crude oil. They compared the amount of precipitated wax of 17 crude oils with the amount of wax determined by the acetone precipitation method with high accuracy [1]. Yalaoui and his team used the CPMG sequence to study the behavior of crude oil in the crystal network formed during the crystallization process and illustrated the existence of less mobile liquid regions in the crystal network [2]. Zhao and his team used CPMG sequences to characterize a model wax system in deuterated toluene and generated wax precipitation curves by quantifying the change in signal upon the action of various waxes and wax inhibitors. Direct comparison of the wax precipitation curves with DSC demonstrated both methods. with good consistency results.

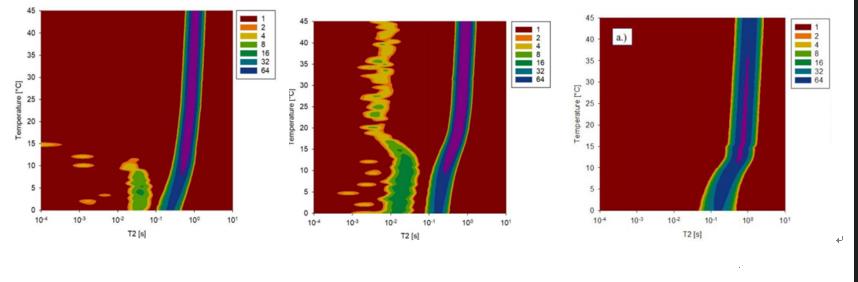

a. 5% wax solution b.5% wax 1% asphaltene solution C. 5% wax 0.01%PPD

Change of T2 and Strength of Deuterated Toluene Solution with Temperature

What is the principle of low-field NMR technology to study wax crystallization process?

Using a high-resolution NMR approach, Savulescu and his team used a low-field NMR spectrometer at 21M to gain further insight into the interactions behind the wax inhibition mechanism [4]. Wax inhibitors such as pour point depressants (PPDs) and crude oil components such as asphaltenes are used to influence wax precipitation through co-crystallization and complex formation with waxes.

The wax T2 in different formulations has two parts of signals, the main peak of 10-1~1s is the main peak signal of the wax dissolved in the solution, and the peak of 10-3~10-1s is between the liquid phase and the solid, or there is solid wax. Liquid wax signal in the area. The solid wax after crystallization could not be detected in NMR T2.

In Figure a, as the temperature decreases, the dissolved wax signal of the main peak shifts to the left, and the fluidity of the solution decreases. Figure b, c Asphaltene molecules accelerate the precipitation of wax, PPD wax inhibitor forms a complex through co-crystallization with wax, and this part of the signal cannot be detected in the NMR T2 spectrum.

Quantitative detection of paraffin content and solid paraffin content in solution can be achieved by the amount of NMR signal.

Using NMR methods allows us to understand and quantify at high resolution how asphaltenes or other inhibitors in an evolved aggregate state affect the mobility of dissolved waxes in the wax crystal network. New methods and new breakthroughs in the wax precipitation mechanism may be practically extended to actual crude oil production in the future.

References:

[1]Batsberg Pedersen, W.; Baltzer Hansen, A.; Larsen, E.; Nielsen, A. B.; Roenningsen, h. PAG. Wax Precipitation from North Sea Crude Oils. 2. Solid-Phase Content as Function of Temperature Determined by Pulsed NMR. Energy Fuels 1991, 5 (6), 908−913. D

[2] Yalaoui, I.; Chevalier, T.; Levitz, P.; Darbouret, M.; Palermo, T.; Vinay, G.; Barré, l. Probing Multiscale Structure and Dynamics of Waxy Crude Oil by Low-Field NMR, X-Ray Scattering, and Optical Microscopy. Energy Fuels 2020, 34 (10), 12429−12439.

[3] Zhao, Y.; Paso, K.; Norrman, J.; Ali, H.; Sørland, G.; Sjöblom, J.Utilization of DSC, NIR, and NMR for Wax Appearance Temperature and Chemical Additive Performance Characterization. j. Therm. Anal. Calorim. 2015, 120 (2), 1427−1433.

[4] Savulescu G C , Simon S , Srland G , et al. New Nuclear Magnetic Resonance Approaches on the Evolution of Wax Mobility during Wax Crystallization [j]. 2021.

mohoso

mohoso