Tecnología RMN de campo bajo del experimento de inundación de polímeros de inyección central

What is Polymer Flooding

Polymer flooding is a means of increasing production by injecting polymer into the formation for oil flooding. Macroscopically, it mainly depends on increasing the viscosity of the displacing fluid and reducing the mobility ratio between the displacing fluid and the displaced fluid, thereby expanding the swept volume. The stretching effect on the oil film or oil droplets increases the carrying force and improves the microscopic oil washing efficiency.

Due to its relatively clear mechanism and relatively simple technology, the polymer flooding technology has been researched relatively early in various countries. Desde 1970, the Soviet Union, Canada, the United Kingdom, Francia, Romania and Germany and other countries have rapidly carried out polymer flooding field experiments. Since the 1960s, more than 200 oil fields or blocks have been tested for polymer flooding. Polymer flooding is to add a small amount of water-soluble polymer to the injected water to improve the mobility ratio and increase the sweep coefficient by increasing the viscosity of the water phase and reducing the permeability of the water phase, thereby increasing the oil recovery rate of crude oil.

The polymer flooding experiment is a relatively economical enhanced oil recovery method. It is generally believed that the main function of the polymer is to increase the viscosity of the water phase and decrease the permeability due to the retention of 5I by the polymer, which leads to a significant decrease in the mobility of the displacement fluid in the oil layer. The results of nuclear magnetic resonance imaging show that polymer flooding can improve the pore utilization coefficient, thereby improving the oil displacement effect. The research also shows that the viscoelasticity of the polymer solution also has a certain effect on improving the oil displacement effect.

Introduction of Low Field NMR Technology

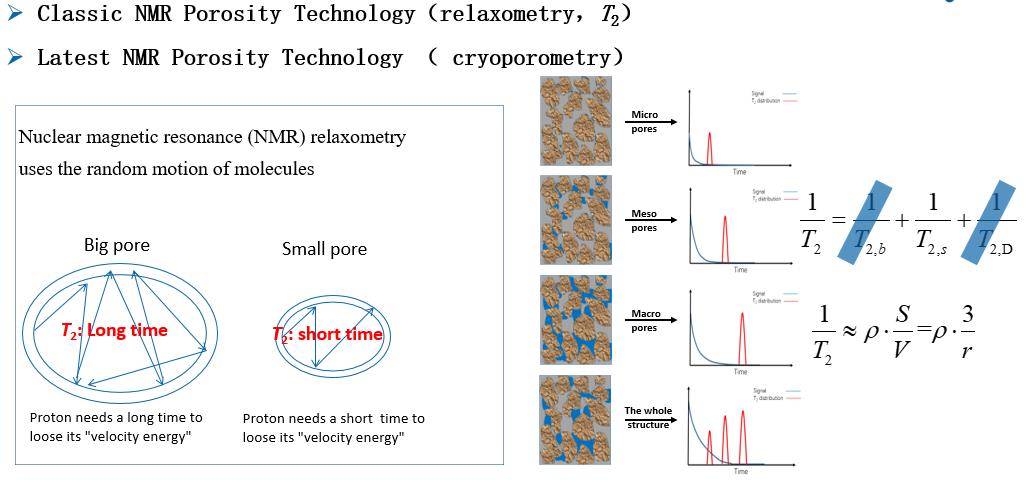

Low-field NMR technology mainly detects H protons but can also be used for F signal testing. After the H-containing sample is excited by a specific frequency of radio frequency, an NMR signal is generated. The H NMR signal corresponds to two main parameters, T1 y T2. By testing the relaxation time of T1 and T2 and modeling, it can be used for oil exploration, geotécnico, energy and other research.

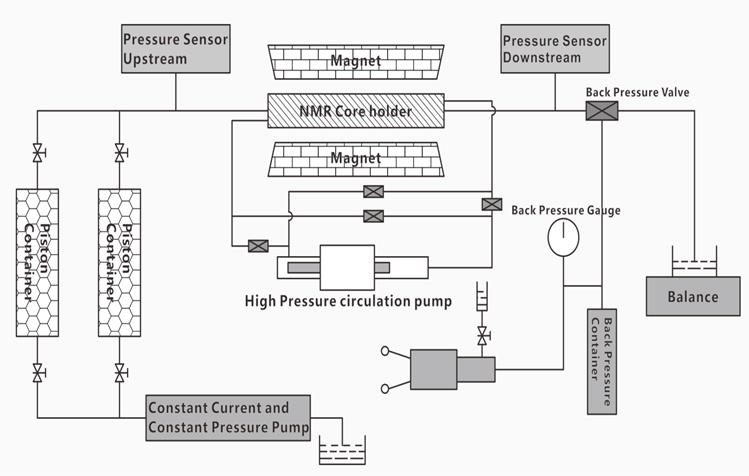

Principle and Device of Low-Field NMR Technology for Core Injection Polymer Flooding Experiment

On-line MRI technology uses a strong magnetic field and electric field gradient to scan the signal of the sample to be tested through an MRI scanner. In the petroleum exploration and development industry, it is often used to analyze the relaxation time of the reservoir fluid to image the oil-water distribution in the reservoir. . The NMR test signal comes from hydrogen atoms. The more hydrogen atoms, the stronger the signal. Sin embargo, because there are hydrogen atoms in water and crude oil, it is difficult to distinguish the signals of water phase and oil phase. Since fluorine oil has no hydrogen atoms, fluorine oil is used instead of crude oil for experiments, so that the measured signals are all water phases. Since only hydrogen atoms exist in the water phase in the experiment, the remaining oil saturation in the core is related to the NMR T2 spectrum signal. Por lo tanto, the distribution of remaining oil after water flooding and polymer flooding can be calculated by analyzing the NMR T2 spectrum relaxation time change and compare.

mohoso High temperature and pressure modules

mohoso

mohoso