Introducción

The gas-water seepage ability has an important influence on the production of coalbed methane well. The gas-water two-phase flow process is accompanied by every link of coalbed methane development, and spontaneous infiltration is almost the case of all water-loving coal reservoirs. Sin embargo, the study on the permeability damage and its influencing factors caused by osmosis is not systematic and has not given a clear conclusion.

On the one hand, it can promote gas desorption in coal seam, which is beneficial to gas reservoir development. Por otro lado, the process of infiltration increases the water saturation of the reservoir and causes the gas permeability to decrease significantly, which is a disadvantage Sistema de RMN de núcleo de roca. Por lo tanto, the purpose of this paper is to explore the law of coal permeability and its influence on permeability.

Samples

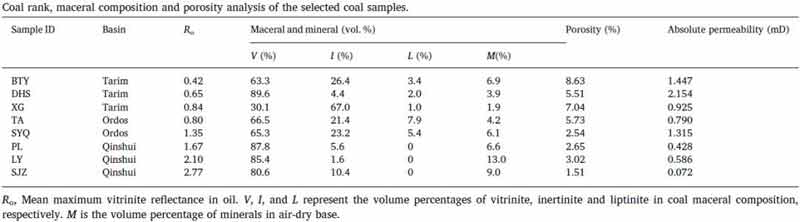

The samples of the infiltration experiment were taken from three basins, qinshui basin, ordos basin and tarim basin, and covered from low-order coal to high-order coal. The basic parameters of the sample are shown in the following table:

In the process of drilling coal core, the influence on the original wettability of core should be minimized. The core size is about 50mm long and 25mm in diameter, which makes it easy for nuclear magnetic testing. The periphery of the core is smoothed with sand to ensure that gas does not flow from the edge of the core during gas displacement.

Método & Apparatus

The overall experimental process includes the experimental preparation stage, wettability evaluation stage, spontaneous infiltration experiment stage, and gas displacement permeability measurement stage.Spontaneous Osmosis Experiment

3.1 Spontaneous Osmosis Experiment

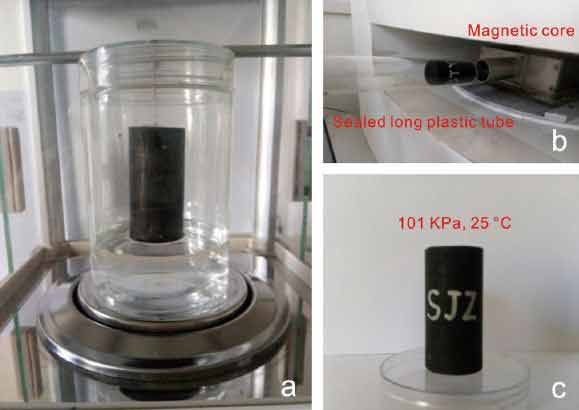

The samples were first dried for 24 hours in a drying box at 105°C, and the thoroughly dried samples were first subjected to a nuclear magnetic test as a base signal. In the seeping experiment, the core is suspended in a closed container with thin lines containing deionized water as the seeping fluid. The height of the thin lines is adjusted so that the bottom surface of the coal rock is in contact with the surface of water. The water is sucked from the bottom of the coal rock (in the same direction of seeping), as shown in figure 1.

During the nuclear magnetic measurement, the core was placed in a long-necked glass tube to prevent water evaporation caused by heat release from the nuclear magnetic coil. The experiment was conducted at room temperature, about 26°C The amount of water imbibed by coal and rock is detected by nuclear magnetic T2 spectrum. Considering that the imbibition speed is fast at first and slow at last, measurements are made every 10 minutes at the initial stage of imbibition and every 2 hours at the late stage of imbibition.

3.2 Gas Displacement Experiment

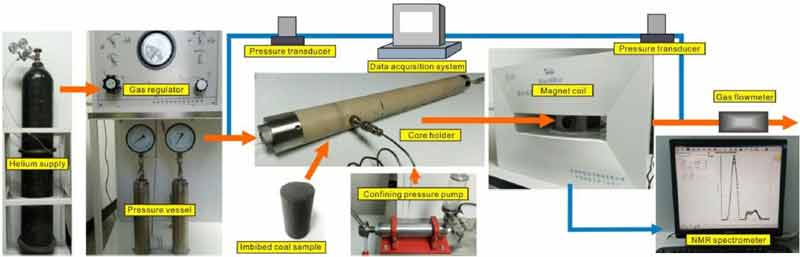

In order to explore the influence of water on gas seepage capacity after imbibition, gas displacement experiments were also carried out. Helium is used for gas displacement, because helium is a non-adsorbent gas and will not change the pore size due to gas adsorption. In order to simulate the formation conditions, the confining pressure of 2.8mpa was applied to the low-order coal and 3.2mpa to the high-order coal, which was estimated from the sampling depth. The measuring device of gas displacement experiment is shown in figure 2. The main body consists of core displacement device, nuclear magnetic measuring device and data acquisition system. The NMR instrument is Meso23-060H-I for Niumag.

mohoso

mohoso