Results & Discussion

4.1 NMR Spectrum Characteristics of the Infiltration Process

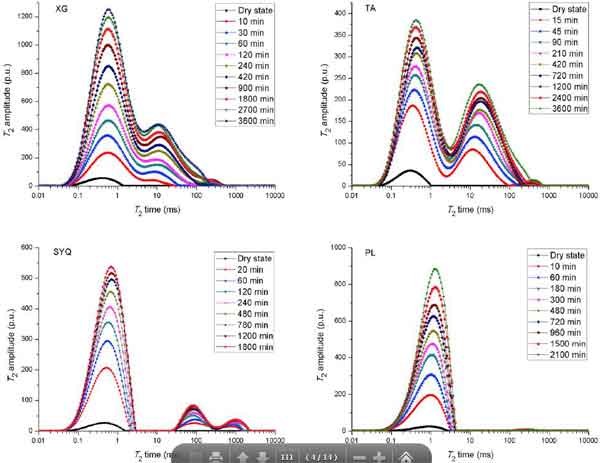

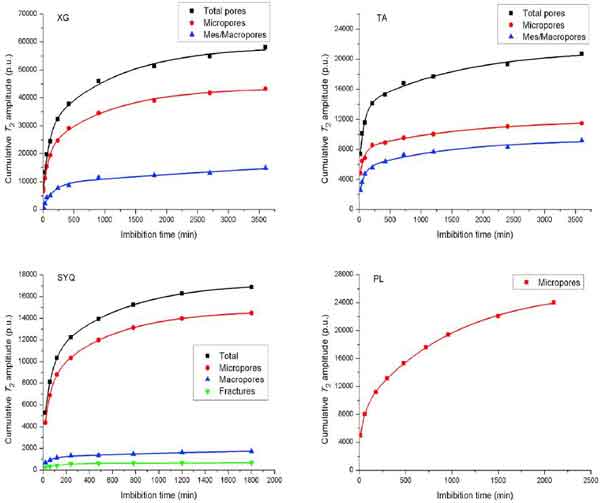

According to figure 3, the low-order coal has two distinct continuous spectral peaks, and the peak on the left is roughly located between 0.1~1ms at the relaxation time, representing the surface relaxation of water in the pore. The peak on the right is approximately 5~100ms, mainly due to surface relaxation in the large pore. The spectral peak shows that the pore connectivity is good. The high-order coal samples showed only a spectral peak of a small pore at 0.1~1ms.For the high-order coal sample SYQ, a second smaller NMR peak appeared at the relaxation time of more than 100ms and was not connected to the spectral peak of the pore, which was caused by the relaxation signal of water in the microcrack. In the process of infiltration, the signals of pore and fissure water at all levels increase with time, but the increase range of different pores is different (figure 4).

4.2 The influence of coal grade on osmosis

4.3 Effect of wettability on osmosis

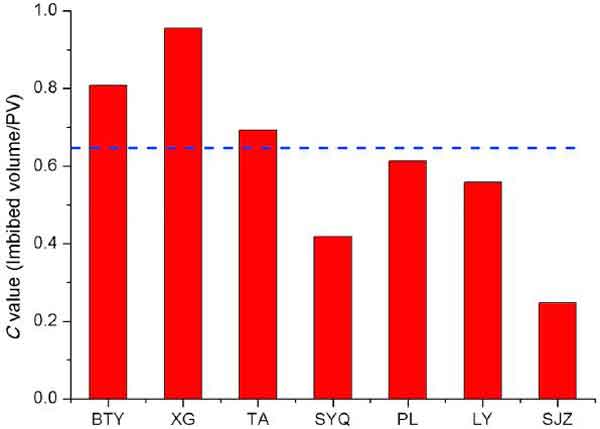

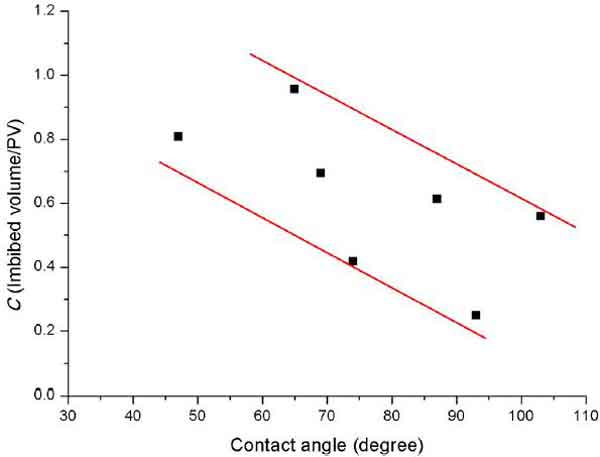

Through the wetting Angle test, the hydrophilic ability of different coal rocks was obtained. The more hydrophilic the sample was, the more water would spread on its surface and interior, thus displacing the non-wetting phase fluid. The wettability of coal and Rock Core NMR system is affected by many factors such as the composition of coal and rock, fluid properties, test environment and pressure. Figure 6 shows that the imbibition rate of low-order coal is significantly faster than that of high-order coal, which also corresponds to the wettability test results. Through the relationship between the C value and the wetting Angle, it is also concluded that the smaller the wetting Angle is (the stronger the hydrophilicity is), the higher the C value of self-priming ability is.

4.4 Effect of infiltration on gas permeability measurement

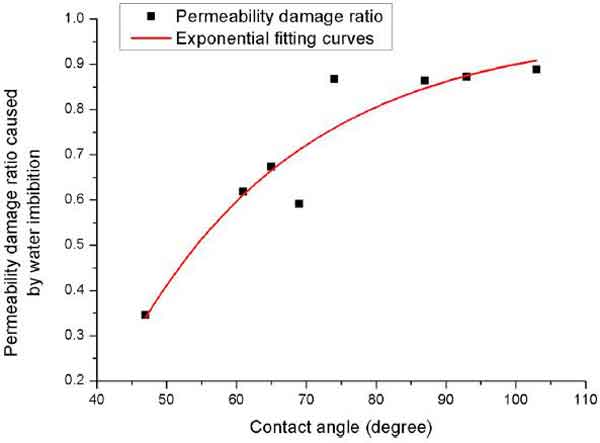

FIG. 7 shows the relationship between permeability damage index and wetting Angle, showing a positive correlation. The four data points on the left of the figure belong to low-order coal, and their wetting Angle is all less than 70 degrees. Due to strong hydrophilicity and good pore connectivity, the C value of low-order coal is larger, that is, the ratio of suction volume to pore volume is larger. However, the permeability damage of low-order coal is less than that of high-order coal.

What is the reason that low order coal has more self-priming and less permeability damage?

According to the analysis, the permeability of low-order coal is nearly two orders of magnitude of that of higher-order coal, which means that water intrusion is more likely to form water lock effect and jamin effect in higher-order coal. Approximately 90% of permeability damage corresponds to 45% water saturation in higher order coal. For low rank coal, however, its pore space is larger, when the water under the effect of capillary force into the core, moisture tend to be along the pore wall invasion, while gas flow in the center of the pore, so have not completely blocked pore water, the water lock effect and jamin effect is not obvious, so the low rank coal is still retained some permeability.

Conclusion

The experimental results show that the imbibition of fluid and coal seam is different for different reservoir types, which has certain guiding significance for the selection of actual hydraulic fracturing and production system. Specifically, for low-order coal reservoirs, their strong hydrophilicity is the key for a large amount of fluid seeping into the coal seam. Therefore, the hydrophilicity of the reservoir can be reduced by means of wetting inversion, so as to reduce the fluid self-absorption. As for the higher-order coal reservoir, it is not very hydrophilic in itself, and the main factor restricting the production is its low permeability. Therefore, in the development process, it is necessary to reduce the damage to the reservoir to increase the gas production.

NIUMAG

NIUMAG

WeChat

Scan the QR Code with WeChat