1.Fondo

The gas-water percolation capacity has an important influence on the production of coalbed methane Wells. The gas-water two-phase flow process is accompanied by each link of the development of coalbed methane, and spontaneous percolation is almost the case of all water-wet coal reservoirs. Sin embargo, there is no systematic study on the damage of reservoir permeability caused by percolation and its influencing factors.

On the one hand, it can promote gas desorption of coal seam, which is beneficial to gas reservoir development. Por otro lado, the process of osmosis increases the reservoir water saturation and makes the gas phase permeability drop significantly, which is the negative side. Por lo tanto, the purpose of this study is to explore the law of coal rock permeability and its impact on permeability.

2.Sample Characteristic

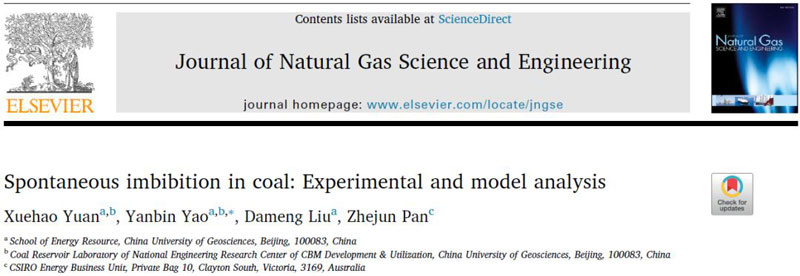

The samples were taken from three basins, qinshui basin, ordos basin and tarim basin, covering from low rank coal to high rank coal. The basic parameters of the sample are shown in the following table:

In the process of drilling coal rock core, the influence on core initial wettability should be minimized. The core size is approximately 50mm long and 25mm in diameter, making it easy for nuclear magnetic testing. The core periphery is polished with sand to ensure that gas does not flow through the core edge during gas displacement.

3 Método & Devices

The overall experimental process includes experimental preparation stage, wettability evaluation stage, spontaneous percolation experiment stage, and gas displacement permeability measurement stage.

3.1 Spontaneous dialysis experiment

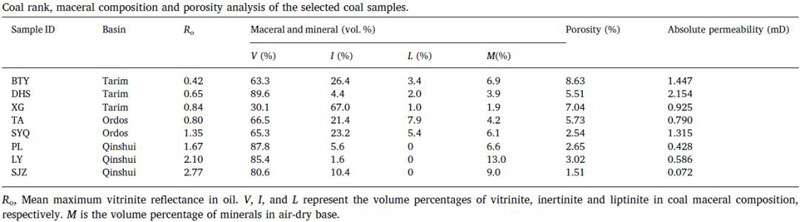

The sample was first dried in a 105°C drying box for 24 hours. The fully dried sample was first subjected to a nuclear magnetic test as the base signal. In the infiltration experiment, the core is suspended in a closed container with thin lines, in which there is deionized water as the infiltration fluid. By adjusting the height of the thin lines, the coal and rock bottom surface is in contact with the water surface, and water is inhaled from the coal and rock bottom (in the same direction) como se muestra en la figura 1.

In order to prevent the water evaporation caused by the heat of the nuclear magnetic coil, the core was placed in the long neck glass tube to conduct the measurement. The experiment was conducted at room temperature, about 26℃. The amount of self-priming water in coal and rock was detected by nuclear magnetic T2 spectrum. Considering that the self-priming rate was first fast and then slow, it was measured every 10 minutes at the initial stage of self-priming and about 2 hours at the later stage of self-priming.

3.2 Gas displacement experiment

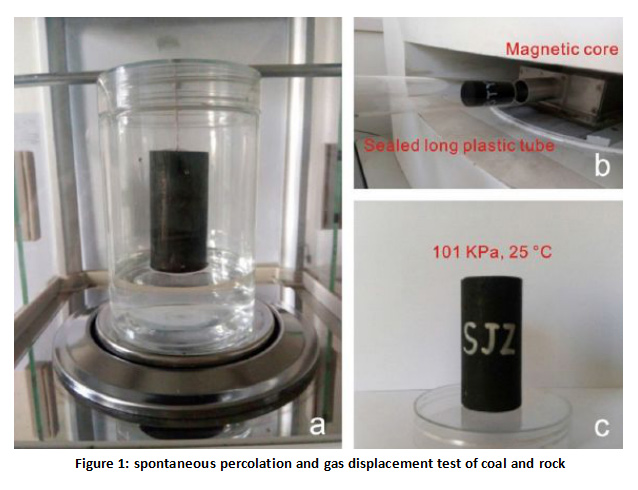

In order to explore the influence of water on gas percolation capacity after self-absorption, gas displacement experiment was also conducted. Helium gas is used for gas displacement, because helium gas is a non-adsorbing gas, which will not change the aperture due to gas adsorption. In order to simulate the formation conditions, the confining pressure of 2.8MPa is applied to the low-order coal and 3.2MPa to the high-order coal, which is estimated from the sampling depth. The measuring device of gas displacement experiment is shown in Figure 2. The main body is composed of core displacement device, nuclear magnetic measuring device and data acquisition system. El Analizador de RMN instrument was Meso23-060H-I analyzed by niumag.

4.Resultados & Discusión

4.1 Characteristics of nuclear magnetic spectrum during osmotic process

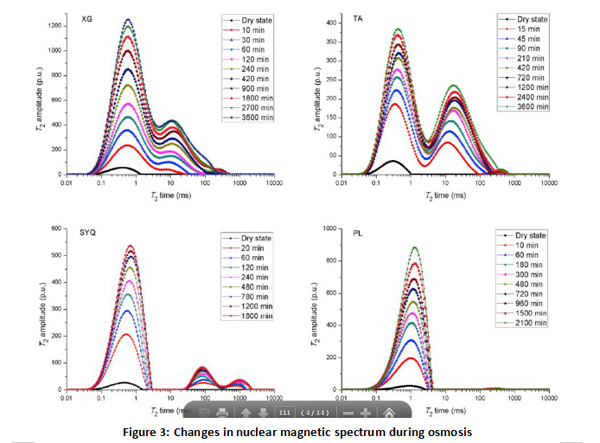

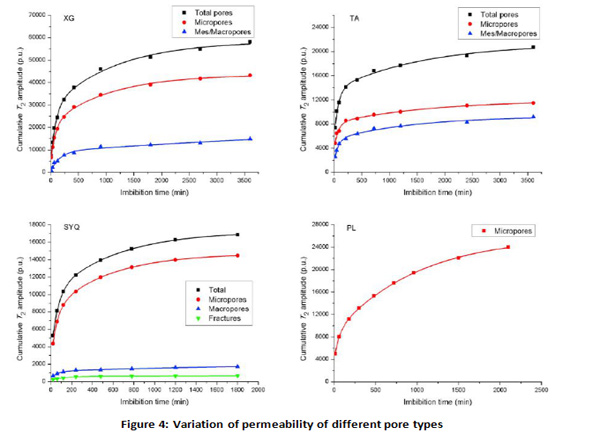

According to Figure 3, the low-rank coal has two obvious continuous spectral peaks, and the peak on the left is roughly between the relaxation time of 0.1~1ms, representing the surface relaxation of water in the pore. The peak on the right is approximately 5~100ms, mainly from the surface relaxation in the large pore. The spectral peaks showed that the pore connectivity was good. The high order coal samples show only one spectral peak at 0.1~1ms.For high-order coal sample SYQ, a second smaller nuclear magnetic spectrum peak appeared at a relaxation time greater than 100ms, and was not connected with the spectral peak of the pore, which was caused by the relaxation signal of water in the microfracture. In the process of osmosis, the water signal of all pore cracks increases with time, but the increase amplitude of different pores varies (HIGO. 4).

4.2 Effect of coal grade on permeability

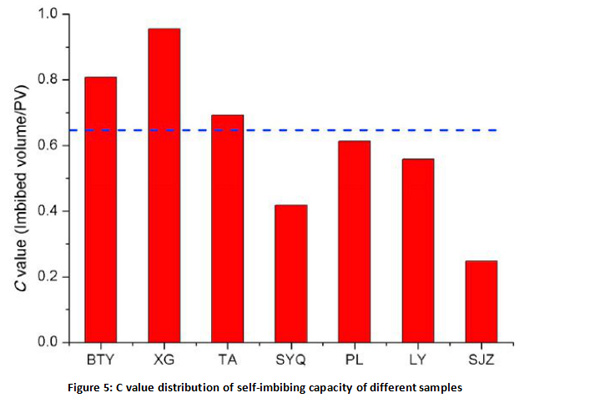

C value can be used to evaluate the effect of coal grade on spontaneous infiltration. It is a parameter used to characterize the degree of imbibition, which is equivalent to the ratio of maximum imbibition volume to pore volume. Cifra 5 shows the distribution of C value of self-absorption capacity of different samples. The average value of C value of low-rank coal is 0.81, and the average value of C value of high-rank coal is 0.46. This shows that low-rank coal has stronger self-absorption capacity than high-rank coal. Al mismo tiempo, it is found that C value is equal to 0.65, which can be roughly used as the dividing line between low rank coal and high rank coal through self-suction experiment.

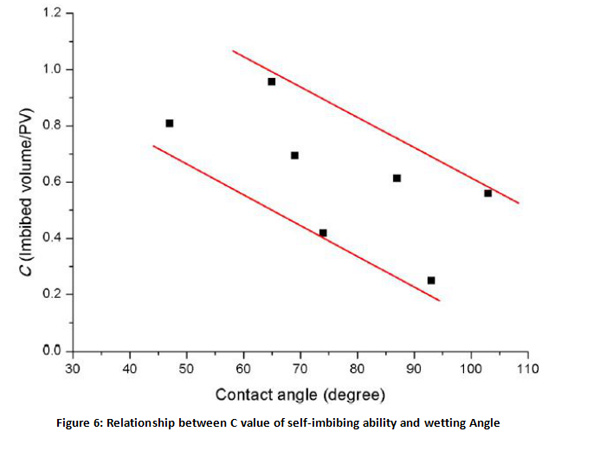

4.3 Effect of wettability on dialysis

By testing the wetting Angle, the hydrophilic ability of different coal rocks is obtained. The more hydrophilic the samples are, the more easily the water spreads on the surface and inside, thus displacing the non-wetting phase fluid. Wettability of coal and rock is influenced by many factors such as coal and rock composition, fluid properties, testing environment and pressure. HIGO. 6 shows that the self-priming rate of low rank coal is significantly faster than that of high rank coal, which is also corresponding to the test results of wettability. According to the relationship between the C value and the wetting Angle, it is also concluded that the smaller the wetting Angle (the stronger the hydrophilicity), the higher the C value of the self-absorption ability.

4.4 Effect of percolation on gas permeability measurement

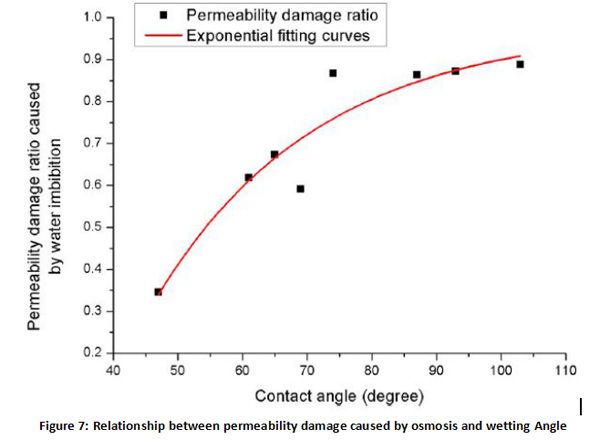

Cifra 7 shows the relationship between permeability damage index and wetting Angle, which shows a positive correlation. The four data points on the left of the figure belong to low-rank coal, and their wetting angles are all less than 70 degrees. Due to strong hydrophilicity and good pore connectivity, the C value of low-rank coal is larger, eso es, the ratio of suction volume to pore volume is larger. But the permeability damage of low rank coal is less than that of high rank coal.

What causes low rank coal to absorb more and permeability damage less?

The permeability of low rank coal is nearly two orders of magnitude of that of high rank coal, which means that water lock effect and jamin effect are more easily formed in high rank coal by water intrusion. Acerca de 90% permeability damage corresponds to 45% water saturation in higher rank coal .For low rank coal, sin embargo, its pore space is larger, when the water under the effect of capillary force into the core, moisture tend to be along the pore wall invasion, while gas flow in the center of the pore, so have not completely blocked pore water, the water lock effect and jamin effect is not obvious, so the low rank coal is still retained some permeability.

4.5 Guiding significance for gas reservoir development

The experimental results show that the self-priming effect of fluid and coal seam is different for different reservoir types, which has certain guiding significance for the selection of actual hydraulic fracturing and production system. Específicamente, for low-order coal reservoirs, its strong hydrophilicity is the key to a large amount of fluid osmosis into the coal seam, so the hydrophilicity of the reservoir can be reduced by means of wetting inversion, thereby reducing the fluid self-absorption. As for high-order coal reservoirs, they are not very hydrophilic, and the main factor restricting production is their low permeability. Por lo tanto, in the development process, reservoir damage should be minimized to improve gas production.

mohoso

mohoso