Pore Size Distribution of Cementitious Materials Study by NMR

Cement-based materials are commonly used in construction, including cement, concrete, mortar, etc. Their pore structure and performance directly influence the safety and service life of buildings. Traditional material testing methods typically rely on physical properties or chemical composition for analysis, but these methods have some drawbacks, such as the need for sample preparation, destructive testing, and long testing times.

Currently, low-field nuclear magnetic resonance (NMR) technology is considered one of the most effective methods for measuring porous materials due to its efficiency and non-destructive nature. Low-field NMR technology can analyze the water content, pore structure, and permeability of materials without damaging the samples, allowing for the evaluation of the performance and quality of cement-based materials.

Regarding the evaluation of the impact of additives on the pore structure of cement-based materials using low-field NMR technology, here are some key points from selected scientific articles:

1. Evaluation of the effects of CEA and MEA additives on pore structure:

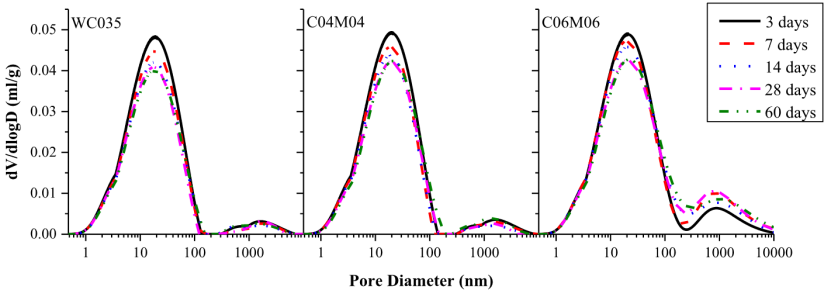

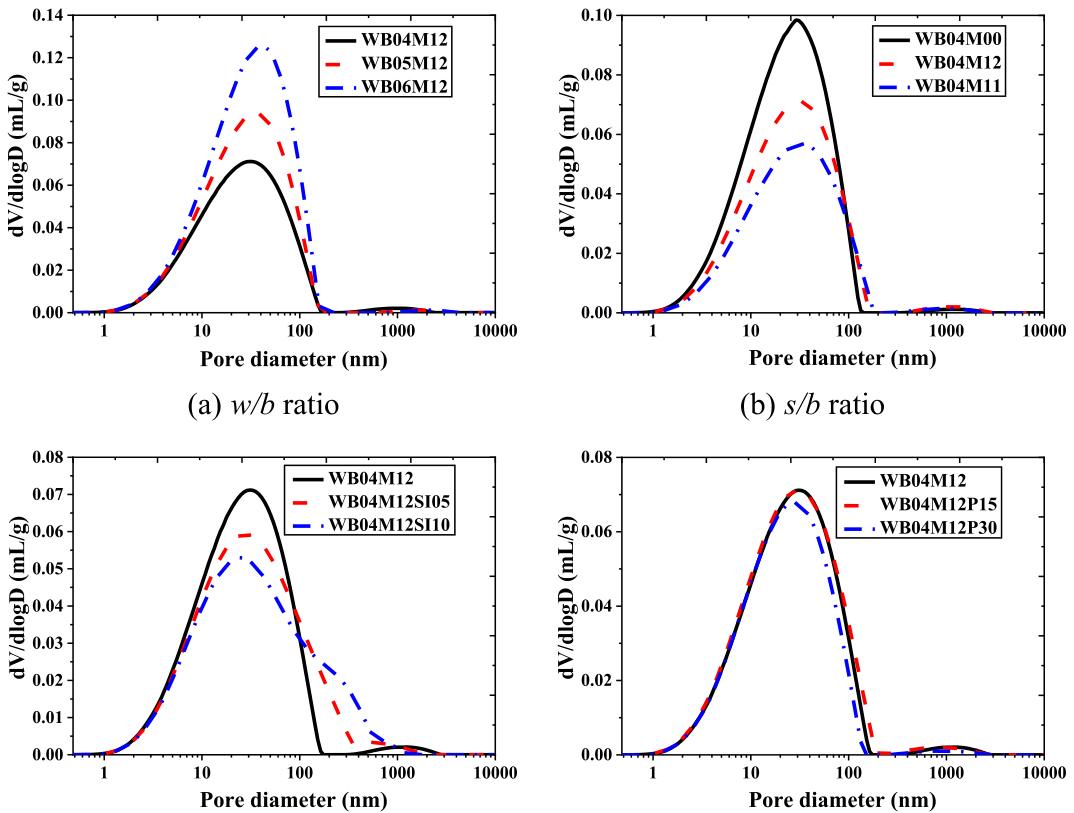

High-strength and high-performance concrete is prone to cracking in the early stages due to significant thermal and autogenous shrinkage under restrained conditions. Additives based on CaO (CEA) and MgO (MEA) are widely used to compensate for this shrinkage, but there is little research on using a combination of CaO and MgO to address the pore structure issues of concrete. This study used low-field NMR technology to investigate the effects of CEA and MEA content, curing temperature, and other factors on the early-stage mortar pore structure.

Experimental results show that the combined use of CEA and MEA has a significant impact on the mortar’s pore structure throughout the testing period. The addition of CEA reduces the pores as the curing progresses, but the addition of both CEA and MEA initially reduces the pores, followed by an increase over time, which also increases with the content of CEA and MEA. Considering the content of CEA and MEA, curing temperature, and other factors, a new model for analyzing the mortar’s pore structure was proposed. Compared to traditional models, this model’s predictions show good agreement with test data and can provide reference for mitigating early-stage concrete shrinkage issues in engineering applications [1].

Figure 1: Variation of PSD of Mortar with Different CEA and MEA Contents over Time.

Figure 2: Variation of PSD of Mortar at Different Curing Temperatures over Time.

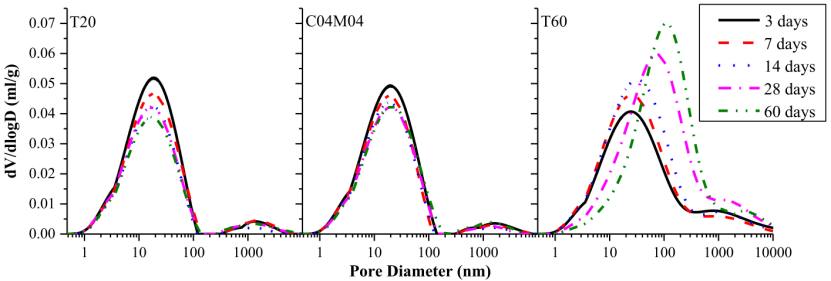

2. Experimental analysis of the relationship between pore structure and capillary water absorption characteristics of cement-based materials:

Capillary absorption capacity has a significant impact on the durability of concrete and is closely related to the pore structure.

In this study, the pore structure and capillary water absorption of the samples were determined using low-field nuclear magnetic resonance and gravity methods, respectively, considering various influencing factors.

The experimental results show that the most probable pore size and equivalent pore size of cement-based materials increase with an increase in water-cement ratio (w/c) and fly ash (FA) content, but decrease with increasing curing time and cement-sand ratio (c/s). The porosity of cement-based materials increases with an increase in w/c and c/s, decreases with increasing curing time, and then increases with increasing FA content [2].

Figure 3: Size Distribution of Pore Diameter in Samples Influenced by Different Factors.

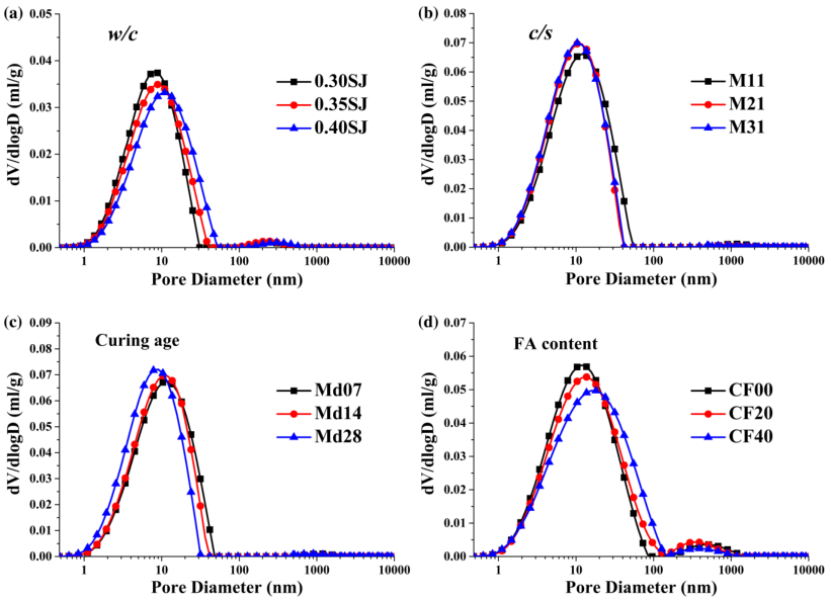

3. Effects of Temperature Rise Inhibitors on Early Cement Slurry Pore Structure:

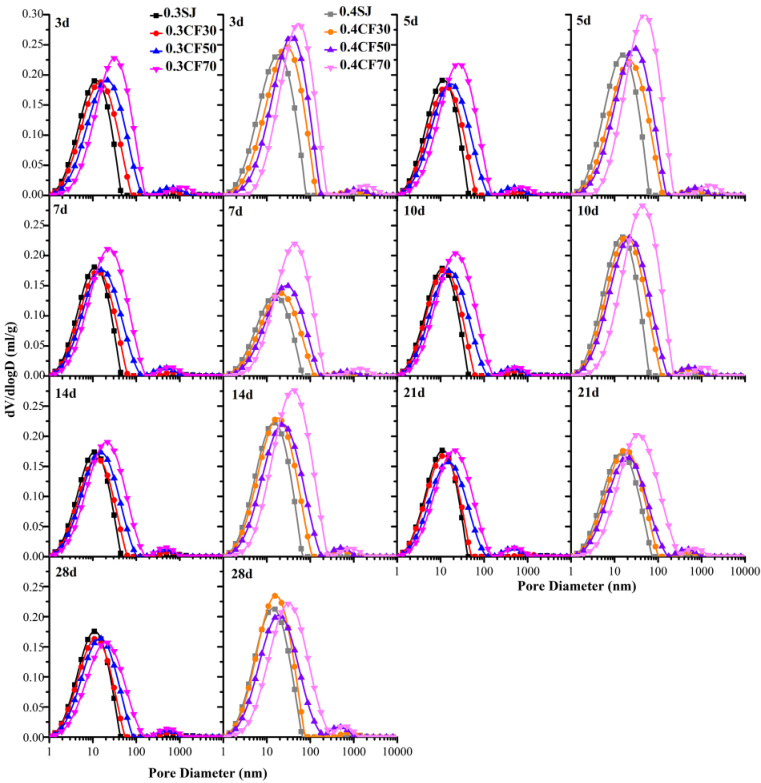

In practical construction projects, high-strength and high-performance concrete (HSHPC) often experiences early cracking due to temperature decrease (thermal shrinkage) and autogenous shrinkage. To address this issue, temperature rise inhibitors (TRI) and shrinkage-reducing agents (SRA) are used to improve the characteristics of HSHPC. In this study, low-field nuclear magnetic resonance (LF-NMR) technology was employed to test the effects of water-cement ratio (w/c) and the content of TRI, SRA, and other additives on the pore size distribution (PSD) and porosity of early cement slurry.

The test results show that the PSD of the samples typically includes two peaks. The combination of SRA and TRI has a noticeable impact on the PSD of the samples. The porosity increases with an increase in w/c and SRA content but decreases with an increase in TRI content. Within 28 days, the samples that have both SRA and TRI added exhibit significantly lower porosity compared to samples without SRA and/or TRI [3].

Figure 4: PSD of Cement Slurry with Different TRI and SRA Contents.

4. Durability Evaluation of Cement-Based Materials:

Durability is one of the key properties for evaluating cement-based materials (CBMs) and is significantly influenced by water migration within CBMs. Permeability (S) and capillary coefficient (k) are two important parameters for assessing the water migration behavior of CBMs, and they are closely related to the microstructure of cement-based materials. In this study, low-field nuclear magnetic resonance (LF-NMR) was used to measure the pore size distribution and porosity of mortar. Based on the LF-NMR and gravity methods, the S and k values were re-calculated.

The results show that the equivalent pore radius (r) of mortar, determined by the pore size distribution, increases with an increase in the water-to-binder (w/b) ratio and sand-to-binder (s/b) ratio, and decreases with a reduction in the content of silica fume (SF) and superabsorbent polymer (SAP). The S value improves with an increase in the w/b ratio and SF content, and decreases with an increase in the s/b ratio. The trend of mortar’s k value is similar to that of the S value [4].

Figure 5: PSD of Mortar under Different Influencing Factors.

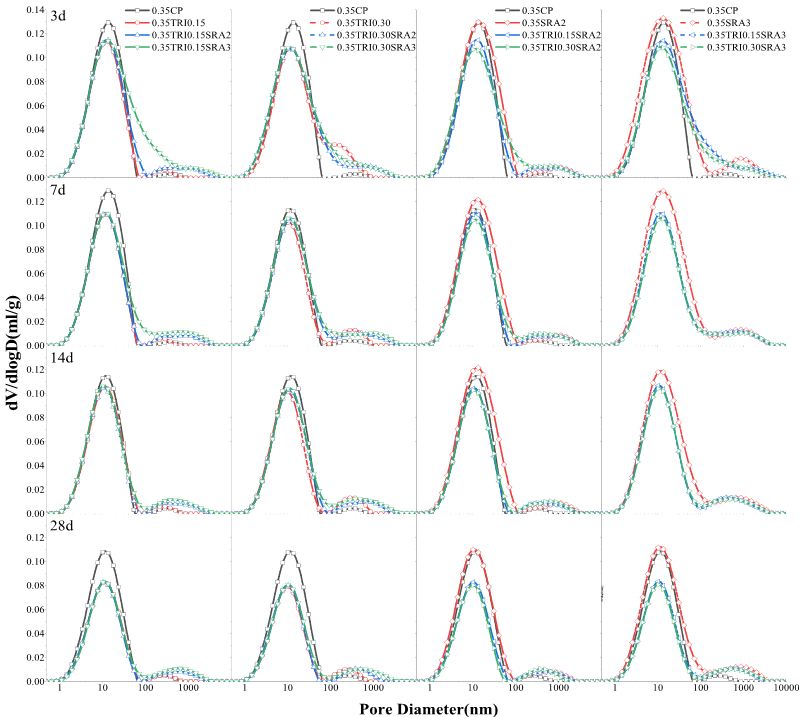

5. Evaluation of Early Hydration Pores in Cement with Fly Ash Addition:

Large quantities of fly ash are commonly used as a partial substitute for cement to improve the workability, durability, and economy of concrete. The pore structure is an important factor affecting concrete performance. In this study, low-field nuclear magnetic resonance (LF-NMR) technology was used to determine the influence of water-to-binder (w/b) ratio and fly ash content on the pore structure of early cement slurry.

The experimental results show that the pore size increases with an increase in fly ash content and w/b ratio but decreases with the progression of hydration time. The porosity increases with an increase in w/b ratio and decreases with the progression of hydration time [5].

Figure 6: PSD of Fly Ash Cement Slurry with Different Fly Ash Contents.

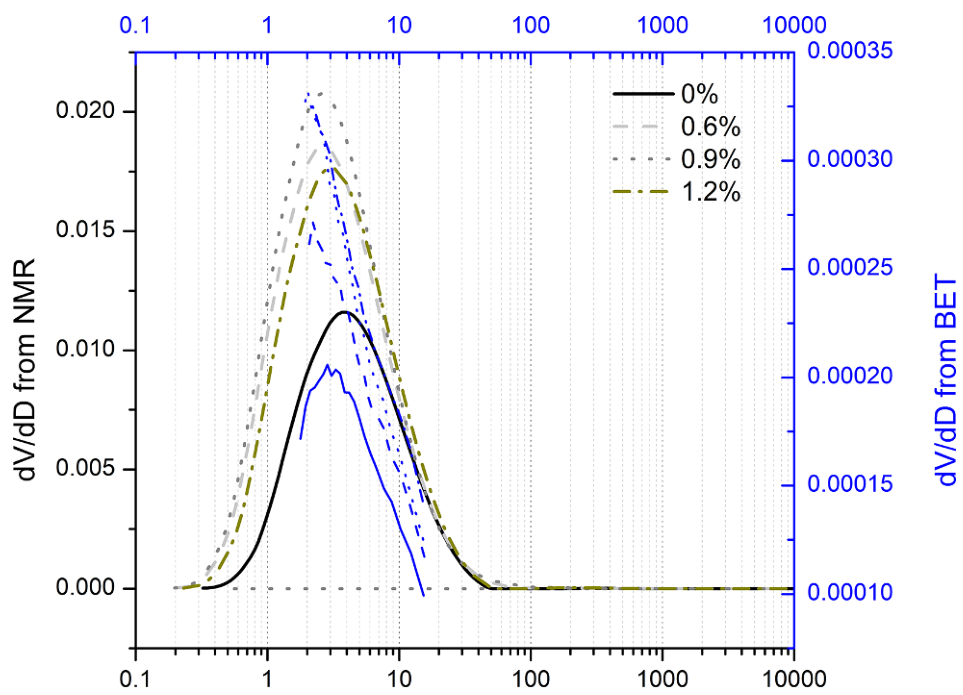

6. Durability Evaluation of Corrosion-Resistant Cement-Based Materials:

Incorporating concrete matrices with corrosion-resistant ions is a common practice to enhance the durability of concrete. Low-field nuclear magnetic resonance (NMR) experimental methods were applied to assess the influence of formate ions on pore surfaces and structure. NMR results indicate that the surface relaxation of cement slurry containing hydrophobic agents decreased to 60% of the reference sample, and there is good consistency between surface relaxation and water absorption. The addition of hydrophobic agents induced changes in the pore structure, resulting in the generation of lamellar crystals that altered the pore surface characteristics, thereby improving the water resistance of the pores in the cement slurry after mixing with the hydrophobic agents. These findings reveal the mechanism through which calcium formate affects the hydrophobicity of cement-based materials and provide insights for enhancing the application characteristics of hydrophobic agents [6].

Figure 7: PSD of Cement-Based Materials with Different Hydrophobic Agent Contents using Adsorption Method and NMR Method.

In conclusion, the application of low-field nuclear magnetic resonance (NMR) technology in cement-based materials provides a non-destructive method for measuring the internal structure and physical parameters of the materials, revealing changes in material performance and properties. It can offer reliable analytical data in various aspects, including moisture content monitoring, pore structure evaluation, hydration reaction analysis, permeability assessment, and aging condition evaluation. This information is of significant importance for improving the quality and performance of cement-based materials and optimizing engineering applications.

Reference:

[1]Zhao H, Li X, Chen X, et al. Microstructure evolution of cement mortar containing MgO-CaO blended expansive agent and temperature rising inhibitor under multiple curing temperatures[J].Construction and Building Materials, 2021, 278(3):122376.[2]Zhao H, Ding J, Huang Y, et al. Experimental analysis on the relationship between pore structure and capillary water absorption characteristics of cement‐based materials[J].Structural Concrete, 2019, 20(1).

[3]Zhao H, Xiang Y, Zhang B, et al. Effects of temperature rising inhibitor and shrinkage reducing admixture on pore structure of early-age cement paste[J].Construction and Building Materials, 2021, 306:124896.

[4] A, Haitao Zhao, et al. Investigation on sorptivity and capillarity coefficient of mortar and their relationship based on microstructure – ScienceDirect[J].Construction and Building Materials, 265[2023-06-27].

[5]Zhao H, Qin X, Liu J, et al. Pore structure characterization of early-age cement pastes blended with high-volume fly ash[J]. Construction and Building Materials, 2018, 189(NOV.20):934-946.

[6]Zhang H, Zhao H, Mu S, et al. Surface relaxation and permeability of cement pastes with hydrophobic agent: Combining 1H NMR and BET[J].Construction and Building Materials, 2021, 311:125264.

NIUMAG

NIUMAG