Solid Fat Content Measurment by NMR

Solid Fat Content

Measurement of solid fat content (SFC) is a common step in the food industry. Solid fat content analysis is very important for food manufacturers producing fatty based foods. Traditional extraction methods for SFC determination are slow, non-repeatable, and require additional chemicals. Direct measurement of SFC by pulsed NMR method can quickly and accurately determine the VALUE of SFC. Pulsed NMR as a method of fat and oil analysis is included in the following test criteria: AOCS Cd 16b-93 in 2000,ISO 8292 in 2008(Europe).

Solid Fat Content Measurment

Solid fat content is the percentage of solids in a fat at a given temperature. Solid fat content (SFC) is an important property that can affect the appearance, flavor, melting rate, shelf life and stability of fat-based foods. In the chocolate industry, for example, the hope is to create products with the ideal solid fat content that will keep chocolate solid at room temperature but still provide consumers with the experience of “melting in the mouth.” Understanding the various characteristics of products from the solid fat content enables engineering to guide the manufacturing process and produce the best quality products.

Solid Fat Content Application

The solid fat content determines many important properties of fat, such as appearance, sensory properties, and ductility. SFC also affects the melting characteristics, indicating the behavior of fats at different temperatures. The consistency of an edible oil product depends on the solid content. Other factors such as the variation of the solid fat content with temperature, the sharpness of the melting range, and the crystal morphology determine the extent to which fat can be considered plastic. According to research reports, ideal dispersion occurs in the range of about 15-35% solids, known as the plastic range of fats. An SFC of no more than 32% at 10 ° C is critical for good spreadability, and an SFC between 4 ° C and 10 ° C determines product spreadability at cooling temperatures. SFC at 25 ° C affects plasticity, while SFC at 33 ° C affects taste.

On the other hand, the soybean oil and rapeseed oil we eat are easily oxidized and cannot be reused. The food produced has a short shelf life. To make the most of their resources, food producers use hydrogenated fats to hydrogenate various oils into semi-solid fats. The benefit is that the oil becomes very stable and suitable for food processing, but also creates “trans fats”. Unlike other fats that can be consumed in the diet, trans fats have no health benefits and are not essential nutrients. In contrast, trans fats raise bad cholesterol and lower good cholesterol. Health authorities around the world recommend minimizing trans-fat intake. Some countries have legislated to limit the amount and use of trans fats in food.

Solid fat content analysis is very important for food manufacturers producing fatty based foods. In terms of product process optimization, quality control, food nutrition and health care, compliance with regulations and other aspects, it is necessary to measure the solid fat content.

Solid Fat Content Measurment by NMR

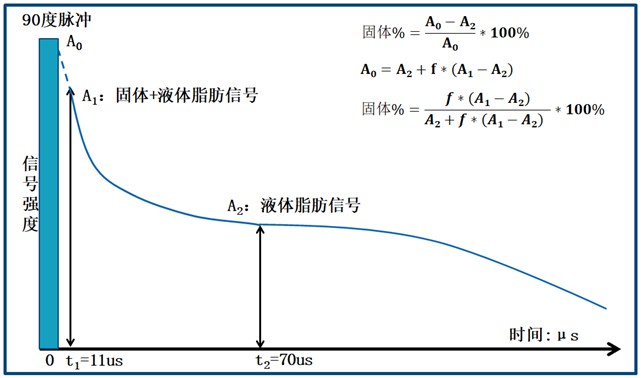

Because H in solid and liquid fat exists in different states, the FID signal decay of pulsed NMR shows different characteristics. Solid fat signals decay rapidly, typically to zero at 70us. Liquid fat signals decay more slowly and are generally considered to have virtually no loss at 70us.

Because the NMR signal from solid decays much faster than that from liquid. Thus, measurements can be made at two points on FID (below), each at the point “T1 =11us”, which corresponds to the sum A1 of the solid and liquid signals. At another point “T2 =70us”, the solid signal at this point has decayed to 0, and the tested signal A2 is only liquid signal. Through calculation, the solid fat content of the sample at the corresponding temperature can be obtained. The curve of temperature and solid fat can be obtained by testing multiple temperatures.

theory of measuring solid fat content by pulsed nmr

Solid Fat Content-Temperature Curve

Advantages of NMR Method for Solid Fat Content

Pulsed NMR is the only direct measurement of solid fat content (SFC), unlike indirect methods such as differential scanning calorimetry (DSC) and dilatometer, which obtain results by measuring the melting point (i.e., the volume change resulting from solid phase melting).

Pulsed NMR has been the preferred method for SFC determination for many years. Pulsed NMR is also the officially recognized standard method for SFC measurement, which has many advantages compared with traditional methods:

● Regardless of the sample’s constant temperature processing, NMR method takes a short time to measure (usually 6 seconds) and the testing process is simple.

● The device is simple to operate, allowing simple training to use it

● NMR is a non-destructive testing technique that allows repeated measurements or other measurements of the same sample

● NMR method is convenient to calibrate, and the instrument is stable and reliable.

Solid Fat Content NMR Analyzer

Solid Fat Content Application list:

● Roast beef fat

● Butter

● Chicken oil

● Coconut oil

● Cream

● Xylanohydride and partially hydrogenated oils

● Lent lard (lard)

● Cream

● Palm oil

● Shortening

NIUMAG

NIUMAG