Spin Finish Detection Technology by Benchtop NMR

What is Cotton Fiber?

Cotton fiber is a seed fiber formed by elongation and thickening of the epidermal cells of the fertilized ovule, which is different from the general bast fiber. Its main constituent is cellulose. Cellulose is a natural polymer compound with the chemical structural formula (C6H10O5). The cellulose content of normal mature cotton is about 94%. In addition, it contains a small amount of pentoses, waxes, proteins, fats, water-soluble substances, ash and other concomitants. Because cotton fiber has many excellent economic properties, it has become the main raw material for textile industry.

Properties of Cotton Fibers:

Cotton fiber has high strength, good air permeability, poor wrinkle resistance and poor stretchability; good heat resistance, second only to hemp; poor acid resistance, dilute alkali resistance at room temperature; good affinity for dyes, easy to dye, the color spectrum is complete, and the color is relatively bright.

Characteristics of Cotton Fiber Fabrics:

- It has strong hygroscopicity and a large shrinkage rate, about 4~10%.

- Alkali and acid resistant. Cotton is not stable to inorganic acids, and even very dilute sulfuric acid will damage it, but the organic acid has a weak effect and has almost no destructive effect. Cotton cloth is more resistant to alkali. Generally, dilute alkali does not have an effect on cotton cloth at room temperature, but after the action of strong alkali, the strength of cotton cloth will decrease. Cotton cloth is often treated with 20% caustic soda solution to obtain “mercerized” cotton cloth.

- Light resistance and heat resistance are average. Cotton is slowly oxidized in sunlight and the atmosphere, reducing its strength. Long-term high temperature will damage the cotton, but it can withstand short-term high temperature treatment at 125~150 °C.

- Microorganisms have a destructive effect on cotton fabrics. Shown in intolerance to mold.

Spin Finish Detection Method of Benchtop NMR

The test methods specified in the current standard GB/T 6504-2008 “Test Method for Oil Content of Chemical Fibers” include extraction method (hereinafter referred to as standard extraction method), neutral soap washing method, optical refractive index method and nuclear magnetic resonance method. This paper mainly introduces the nuclear magnetic resonance method used to detect the oil content of cotton fiber.

Spin Finish Detection Technology (Low Field NMR Method)

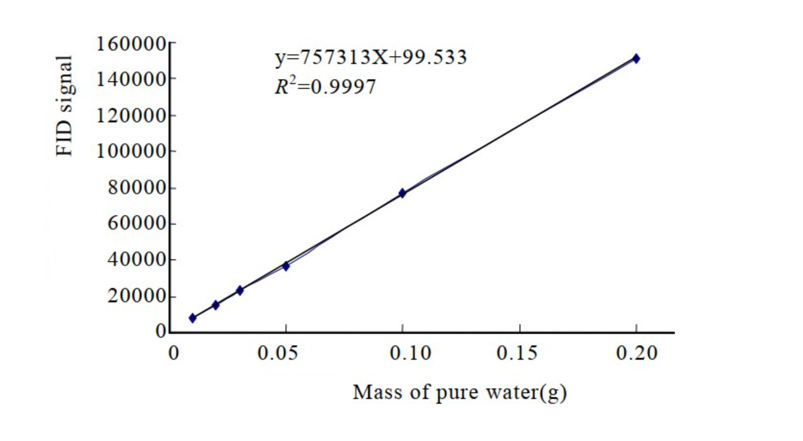

The principle of nuclear magnetic resonance method is to use nuclear magnetic resonance spectroscopy to transmit a pulsed magnetic field to the fiber sample. When the magnetic field is canceled, the response magnetic signal of the sample is detected. Since the signal emitted by the fiber decays faster than the signal emitted by the oil, from the two. The difference can be converted to the oil content of the sample.

Test process: After 3~6 fiber samples with known oil content are used for calibration, the unknown sample can be tested within 30~3 minutes. The testing process is fast and non-destructive, enabling industrial online process testing.

Spin Finish Detection Technology (Low-Field NMR method) Advantages:

- The test speed is fast, and the test can be completed within a few days.

- Instrument calibration is simple.

- Compared with traditional methods, the repeatability and reproducibility of NMR methods are much better.

- Nuclear magnetic method can be used for quality inspection and quality control in industrial production process, saving labor and significantly improving efficiency.

- The instrument is easy to operate, no technicians are required, and untrained personnel are also easy to operate.

- Powerful function, suitable for fiber oiling rate test.

- There is no requirement for the shape of the sample.

- NMR is a non-invasive and non-destructive test, and the same sample can be repeatedly measured as needed.

- The NMR signal is generated by all hydrogen nuclei in the entire sample volume, and the test result does not depend on the sample surface or sample color.

NIUMAG Benchtop NMR for Spin Finish Detection

NIUMAG

NIUMAG