Los materiales de poliuretano son susceptibles al envejecimiento bajo la influencia del calor., oxígeno, y luz, lo que lleva a una degradación estructural y una disminución del rendimiento. This irreversible chemical reaction can be detrimental to the material’s service life. Comprender el mecanismo del envejecimiento es crucial para desarrollar tecnologías antienvejecimiento y crear nuevas, confiable, and long-lasting polyurethane materials.

Resonancia magnética nuclear de bajo campo (RMN-LF) technology emerges as a powerful analytical tool in this context. It measures the relaxation time of hydrogen atoms within the material to assess the extent of polyurethane aging. This technique is sensitive to the mobility of hydrogen atoms, offers simple sample preparation, rapid testing, and is highly suitable for studying changes in cross-linked structures. It holds significant value for adhesive development, curing process optimization, and curing mechanism research.

Ventajas de la tecnología LF-NMR:

– Rapid testing with a green, pollution-free process.

– Non-destructive testing that leaves samples intact.

– Accurate results with quantifiable characterization.

– Easy operation by personnel without specialized training.

Applications of LF-NMR in Polyurethane Aging Research:

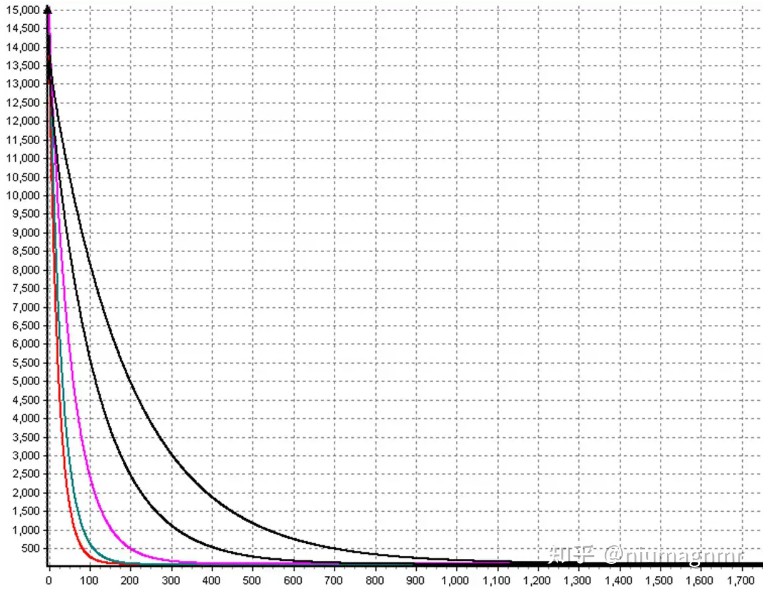

LF-NMR technology can precisely determine the phase transition temperatures of materials. By monitoring changes in molecular relaxation times, it reflects the development of cross-linked structures during curing and natural storage or temperature cycling. This insight is vital for elucidating the aging mechanism of adhesives. Por ejemplo, LF-NMR can measure changes in the transverse relaxation time (T2) of hydrogen atoms in adhesives during curing and aging, revealing internal structural and dynamic information changes.

Además, LF-NMR technology finds applications in material science research, including molecular dynamics analysis, material porosity assessment, and quality control. It allows researchers to gain a deep understanding of material aging processes, providing a scientific basis for developing more effective anti-aging strategies. Although direct applications of LF-NMR in polyurethane aging mechanism studies are not yet widely reported, the technology’s potential in material science suggests its theoretical applicability in analyzing molecular motion and interactions within polyurethane materials, further studying chemical and physical changes during aging.

En conclusión, the integration of LF-NMR technology in the study of polyurethane aging presents a promising avenue for enhancing material durability and performance. Its non-invasive and accurate measurement capabilities make it an indispensable tool in the advancement of polyurethane material science.

mohoso

mohoso