In-situ analysis of changes in the wetting ratio of different pore moisture

The formula of coal wettability:

пт represents the measured porosity of coal pores, and P represents the total porosity of raw coal samples ЯМР-анализатор.

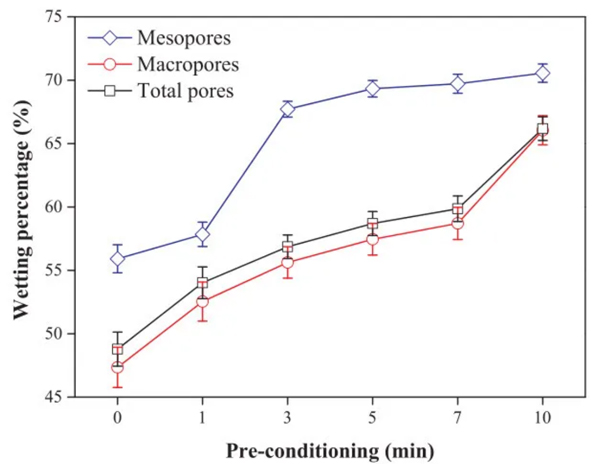

The water wettability of coal pores directly reflects the degree to which the pores on the coal surface are filled with water. The results show that with the increase of pretreatment time, the wettability percentage of mesopores, macropores and total pores all gradually increase.

As the pretreatment time increased from 1 min to 3 мин, the water wettability of coal mesopores increased significantly, indicating that during this period the mesopores were wetted by water at the highest rate.

Впоследствии, the wettability of macropores and total pores began to be slow, but increased rapidly after 7-10 minutes of pretreatment time.

Summary: When the pretreatment time is 1 мин, the water wettability of coal pores is mainly mesopores. When the pretreatment time is 1 ~ 10 мин, the effect of large pores is greater.

интересно, the water wetting percentage curve of large pores is similar to the total pore curve.

The water wetting rate of coal surface pores mainly depends on the amount of water filling large pores. Coal pores undergo a complete drying process before wetting and are considered to be filled with air. Large pores in coal have more space than small pores. Поэтому, the gas pressure of large pores in coal is smaller than that of small pores. Поэтому, large pores are more likely to be filled with water, forming a thicker hydration film on the surface of the coal particles, resulting in reduced floatability of the coal. Поэтому, it can be considered that the wettability of large pore water on the coal surface is the main factor that determines the flotation performance of coal particles

Flotation experiment

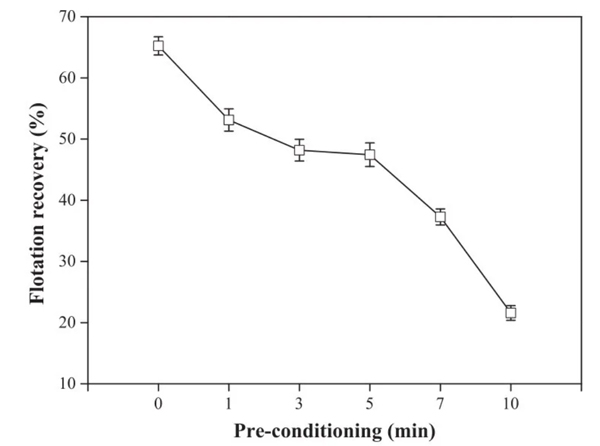

As the pretreatment time increases, the flotation recovery rate drops from 65.23% к 21.58%, and the floatability of coal particles gradually becomes worse and worse.

The surface of the low-rank coal used in this study contains hydrophilic functional groups, making its surface highly hydrophilic. The mesopores, macropores and full pores on the surface of coal particles are easily wetted by water.

These results indicate that long-term treatment not only expels air trapped in the pores, but also easily forms a thick hydrated shell on the surface of coal particles, reducing the efficiency of the attached foamed coal particles.

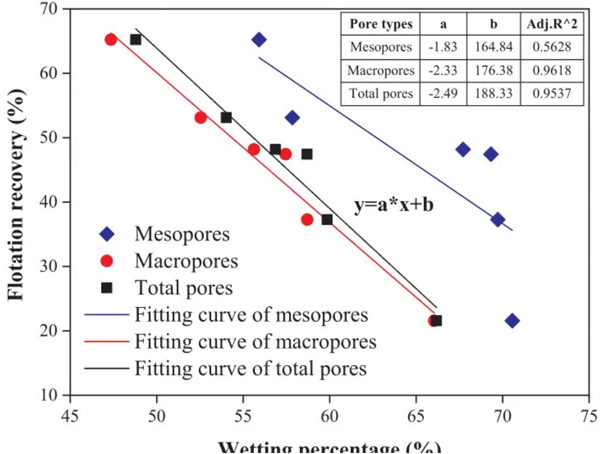

As shown in the figure: the water wetting rate of the mesopores, macropores and total pores is negatively linear with the flotation recovery rate.

The correlation between mesopore water content, macropore water content and total pore water content has a good correlation with the flotation recovery rate, especially for macropores and total pores, the correlation coefficients reach 0.9618 и 0.9537.

This again shows that the water wetting rate of coal pores mainly depends on the extent to which large pores are wetted by water during the pretreatment process.

Заключение

1.The low-grade coal powder is mixed with water for low-speed stirring pretreatment. As the pretreatment time increases, the porosity of the coal surface increases from 11.33% к 15.37%, and the flotation recovery rate is greatly reduced.

2.Large pores are more easily wetted by water than small pores, resulting in a thicker hydration layer on the coal surface, which reduces the floatability of coal particles.

3.There is a clear linear relationship between the macropore and total pore wetting degree and flotation recovery rate, which explains the effect of coal pore water wetting degree on flotation properties.

4.Calculate the wettability of coal pores using the porosity of different pore sizes, and then directly reflect the degree of coal surface pores filled with water according to the water wettability of coal pores, and then reflect the wettability of pores.

Ссылка:

Yuqiang Mao, Wencheng Xia, Yaoli Peng,et,al.

Wetting of coal pores characterized by LF-NMR and its relationship to flotation recovery,Топливо,2020.

Dio: 10.1016/j.fuel.2020.117737

заплесневелый

заплесневелый