Sulfur powder oil content test (low-field nuclear magnetic method)

In the production process of chemical powders (such as sulfur), a certain amount of oil is added according to product quality and characteristic requirements to improve product performance and facilitate production and processing. The powder also contains moisture. The content of these liquids in the powder is an important parameter that affects the quality of the product. To ensure stable product quality, accurate and fast measurements are required. The low-field nuclear magnetic field can quickly complete the oil and water content test, and the sample preparation process is very simple, which provides the possibility to realize the quality inspection and quality control in the industrial production process.

Introduction to traditional test methods:

The traditional method is to use solvent extraction method to detect the oil content in sulfur. The detection process is complicated, time-consuming, and requires professional and technical personnel to operate, and the human error is large. In addition, the extract is a toxic reagent, which is harmful to the health and safety of the operator. There are hazards, and this method is becoming increasingly unacceptable in the industry.

The basic principle of sulfur powder oil content test (low-field nuclear magnetic method):

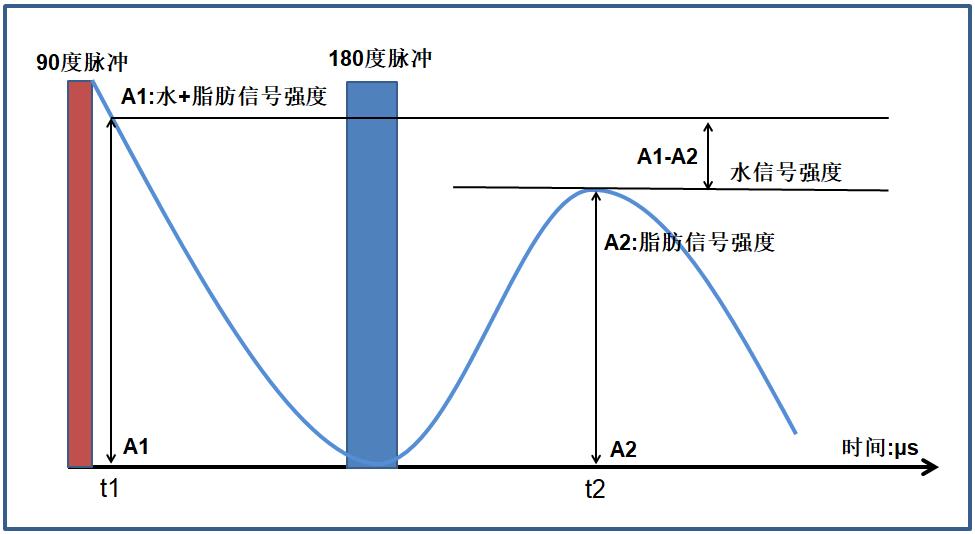

The spin echo sequence is used for measurement. Figure 1 shows the spin echo sequence and the detected nuclear magnetic signal. The free induction decay (FID) NMR signal was measured at t1 after the 90-degree radio frequency pulse. Currently, the signal amplitude (A1) is proportional to the number of H protons in the two liquid phases (moisture and oil) of the sample.

After the 180-degree pulse, the amplitude of the detected spin echo signal is A2. At this time, the water signal has attenuated to 0, and A2 is only the oil signal. Therefore, the difference A1-A2 between the two signal amplitudes is proportional to the water content of the sample.

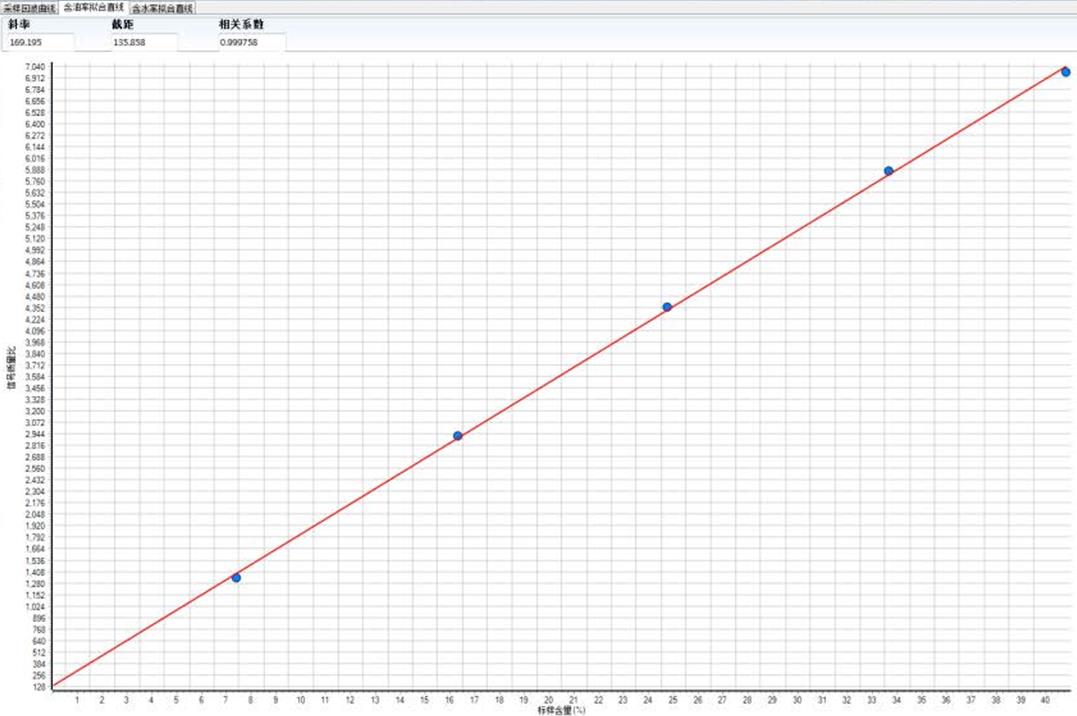

After calibration with a sample with known moisture and oil content, the unknown sample can be tested within 30 seconds to 3 minutes. The testing process is fast and non-destructive, and industrial online process testing can be realized.

In addition, compared with chemical methods, nuclear magnetic methods have better reproducibility, do not require chemical solvents, and can be operated by untrained personnel.

NIUMAG

NIUMAG