Исследование ЯМР в низком поле влияния трещин на извлечение низкопроницаемых пород

Hydraulic fracturing technology can improve crude oil production in tight formations, and the impact of fractures on rock pore recovery is the focus of research. Rock pore structure changes during fracturing, especially lab-made fractures, affecting the mass transfer between matrix pores and fractures. Эти изменения необходимо учитывать для точной оценки влияния трещин на миграцию поровой жидкости.; directly compare samples The results before and after fracturing can lead to some misleading conclusions. в этом исследовании, тяжелая вода и гуаровая камедь использовались для формирования материала для заполнения трещин., which did not invade matrix pores and did not produce detectable NMR signals. By testing the samples filled with this new material and comparing the measurement data of the unfilled samples, the NMR characteristics of the fractures can be obtained, which can be isolated and eliminated for the analysis of the fracture-to-hole-fracture two in the subsequent N2 and CO2 huff and puff experimental studies. Influence mechanism of fluid transport in metasystems.

Low-field NMR analysis experimental results shows:

- Fractures will reduce the sweep efficiency of gas, которую можно частично облегчить, впрыскивая N2 вместо CO2., N2 can elastically support small pores, but the total recovery rate of pure N2 huff and puff is significantly lower than that of CO2.

- Filling fractures will increase pore recovery.

Experimental equipment and methods

The NIUMAG low-field NMR core analysis system (medium size MRI analyzer) использованный в этом исследовании, показан на рисунке. 1.

Medium size NMR analyzer (low-field NMR core analysis system)

Low-field NMR monitoring the process of gas injection huff and puff oil displacement.

- Gas injection huff and puff experiments on saturated oil matrix samples (Донг, 2020а, 2020б).

- The gas injection huff and puff experiment of fracturing samples, Бразильский метод расщепления (БДМ) to create fractures, and saturated oil to determine the total pore distribution after fracturing.

- The gas injection huff and puff experiment of the filled fracture samples was carried out, and the crack filler was configured with heavy water and guar gum to determine the distribution and content of cracks.

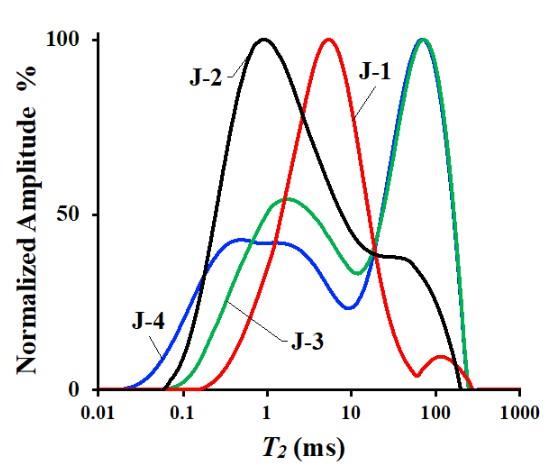

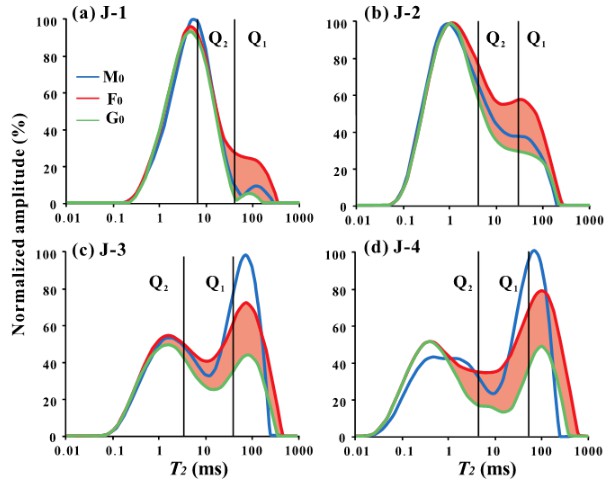

The initial NMR T2 curves of the four samples are shown in Figure 2.

инжир. 2. T2 spectrum of saturated light oil samples before fracturing (J-1 and J-2 are taken from Jimsar Sag, J-3 and J-4 are taken from Xihu Sag)

инжир. 2. T2 spectrum of saturated light oil samples before fracturing (J-1 and J-2 are taken from Jimsar Sag, J-3 and J-4 are taken from Xihu Sag)

Low-field NMR experiment results

1) Fracture distribution (low-field NMR analysis)

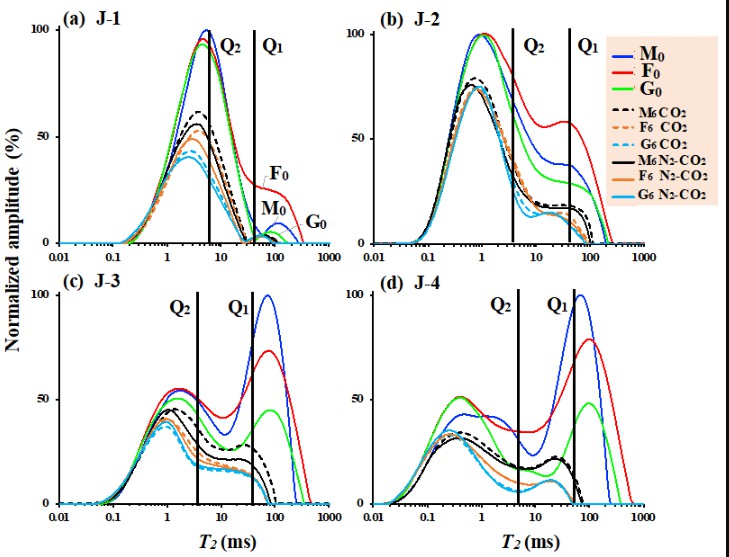

The complete T2 distribution of the fractured fractures was obtained through the guar gum filling experiment (the orange filled area of the T2 spectrum, Фигура 3). Some large-sized fractures were newly added on the right side of the T2 spectrum, and the tiny fractures could extend to T2=1ms. Fracturing changes, the matrix pore structure (М0 против. G0), with varying matrix pore amplitudes and boundaries. Поэтому, clarifying the distribution of fractures and matrix pores is helpful to accurately evaluate the impact of fractures on fluid migration.

Фигура 3. Fracture T2 distribution (Q1 and Q2 are the boundaries between large, medium and small pores)

Фигура 3. Fracture T2 distribution (Q1 and Q2 are the boundaries between large, medium and small pores)

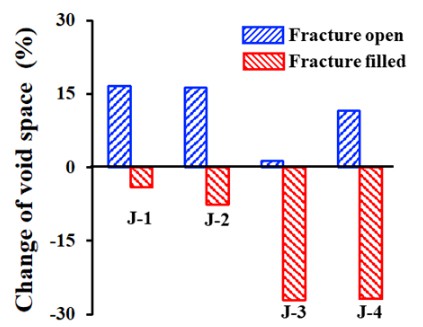

2) Pore increase before and after fracturing

The porosity change rate before and after fracture filling is calculated (инжир. 4). ПВФ (синий) reflects the improvement effect of fracturing on total porosity, и ПВГ (красный) отражает количество пор матрицы, преобразованных в трещины. The effect of fracturing on the pore volume of rock samples with developed micropores (J-1 и J-2) более очевидно, but the proportion of matrix pores converted into fractures is low. The macropore-developed rock samples (J-3 и J-4) have the opposite conclusion, the improvement effect of total pore volume is average, but the proportion of matrix pores converted into fractures is high. Среди них, PVF is obtained by comparing the accumulated nuclear magnetic signal amounts of M0 and F0, and PVG is obtained by comparing the accumulated nuclear magnetic signal amounts of M0 and G0.

Фигура 4. Porosity change rate before and after fracture filling

3) The effect of fracture filling on flow (low-field NMR analysis)

Fracturing changes, the matrix pore structure, and the pore size classification method based on the original sample is no longer applicable here. В этой статье, the textiles of fracture size are used to divide the pores into three categories: large, medium and small to calculate the pore occurrence (such as medium pores Q1)

Фигура 5. Gas injection huff and puff T2 spectrum of fractured rock sample (‘G6 N2-CO2’ is the sixth round of N2-CO2 huff and puff spectrum of fracture filling sample G0)

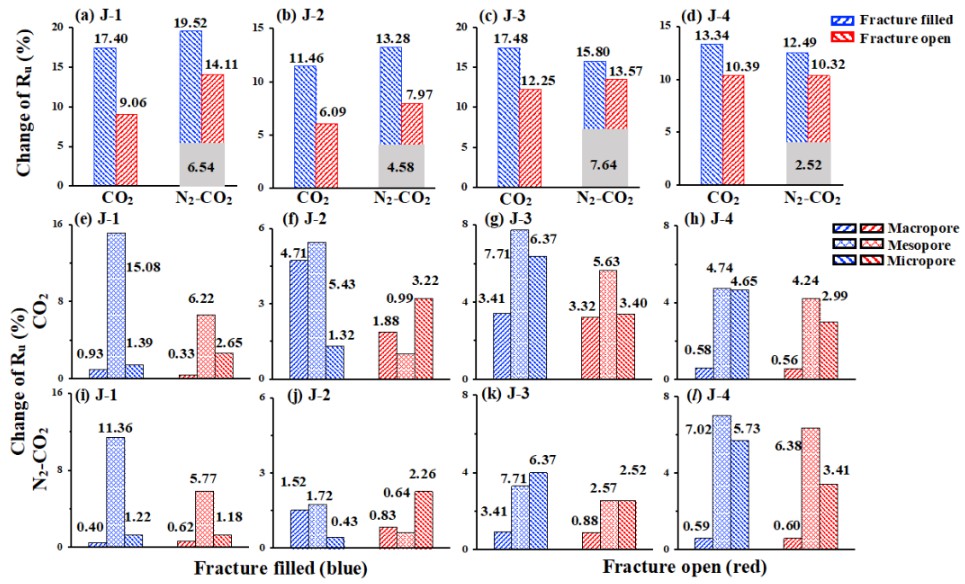

Taking the M0 recovery rate before fracturing as the base value, the incremental recovery rate Ru under the combination of fractures and gas is compared (инжир. 6). The effect of N2-CO2 injection in the matrix rock sample M0 is better than that of pure CO2 (gray, Донг, 2020а). Compared with the pure CO2 huff and puff mode, the effect of N2-CO2 injection in the fracturing samples is better in the micropore-developed rock samples (J-1 и J-2), but the effect is poor in the macropore-developed samples (J-3 and J-2). 4), which is presumed to be related to the elastic supporting effect of N2 molecules on the pores. Fractures store a large amount of gas, особенно CO2, which weakens the kinetic energy of gas diffusion in the matrix pores and reduces total production (красный). Fracture filling treatment can increase the sweep efficiency of the gas in the matrix pores and increase the recovery factor (синий). В краткосрочной перспективе, fracturing will greatly increase production; однако, the gas storage capacity of fractures will adversely affect long-term development.

Фигура 6. Incremental recovery in combined fracture filling and gas injection mode

Relevant literature (low-field NMR analysis):

1) Dong Xu, Шэнь Луи*, Голсанами Насер, Лю Сюэфэн, Это июль, Ван Фэй, Шиин, Сунь Цзянмэн. Как закачка N2 улучшает добычу углеводородов CO2HnP: ЯМР-исследование механизмов вытеснения жидкости. Топливо. 2020а. 278 :118286.

2) Dong Xu, Шэнь Луи*, Лю Сюэфэн, Чжан Пэнюнь, Это июль, Ян Вейчао, СуньЦзяньмэн. ЯМР-характеристика пористой структуры и подвижности флюидов плотных песков: Экспериментальное исследование потенциала увеличения нефтеотдачи CO2. Морская и нефтяная геология. 2020б.118 :104460.

3) Лю Сюэфэн, Сюй Донг*, Голсанами Насер, Лю Бо, Шэнь Луи В., Ши Ин, ГоЦунгуан. ЯМР-характеристика подвижности жидкости в плотных песках: Analysis on the pore capillaries with the nine-grid model. Журнал науки и техники природного газа. 2021. 94.

заплесневелый

заплесневелый