The Introduction Cross-linking Density Measurement by NMR method

Cross-linking density

The cross-linking density describes the number of crosslink bonds in the cross-linking polymer. Generalmente, we can express by the size of the net chain molecular weight, the greater the cross-linking density, the more the number of cross links in the unit volume. For the cross-linking polymer used as plastics such as epoxy resin, the greater the cross-linking density, the better the heat resistance and the tensile strength. Sin embargo, the high degree of cross-linking will lead to a decline in impact strength.

Actualmente, the test method of the cross-linking density of rubber mainly is the stress relaxation, the swelling method and so on. Sin embargo, these methods are time-consuming and low sensitivity, even are destructive to the samples. En años recientes, MRI system for polymer shows a prominent advantage in the test. By measuring the H molecular motion of the hydrocarbon chain, we can obtain the results. NMR can test the cross-linking density of samples in a few seconds in the condition of without chemical intervention and damage.

Cross-linking structure of rubber

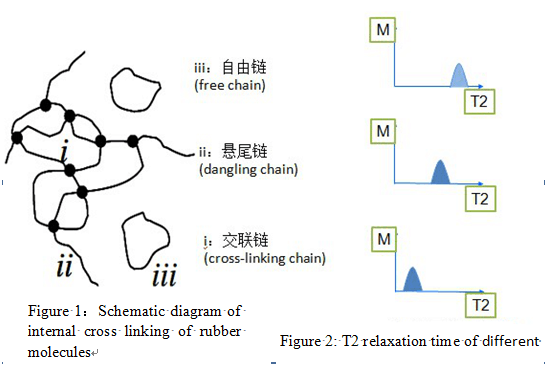

The polymer chains of the rubber are connected to form a three-dimensional mesh macromolecule through the branched chain, which forms the cross-linked structure. the type of the cross link and the cross-linking density are the most important parameters in the structure, indicating the structure of the cross link and the distribution of the density in the rubber molecule chain respectively .As shown in figure 1,There are three kinds of cross-linking chains in the rubber molecule, Cross-linking chains, dangling chains and free chains. The binding force of H proton in each chain is decreased in turn and the T2 relaxation time reflects the degree of freedom of each chain. The assumption is that the signal of T2 in 0.1-1ms is a signal originate from the hydrogen proton on the plastic polymer chain, the signal of T2 in 1-10ms is the hydrogen proton signal from the dangling chain. By using respective T2 relaxation time and a certain analysis model to evaluate the cross link density information.

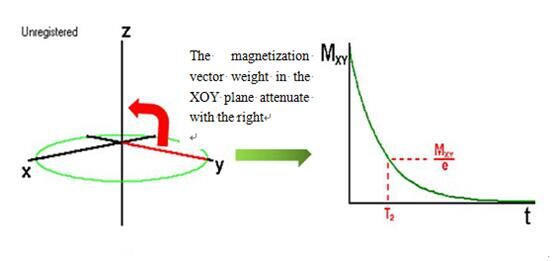

The following figure is the spin-spin relaxation process of hydrogen protons.90 degree RF pulse let the Magnetization intensity rotate to the Y axis, At the time of MXY=M0 after adding 90 degree RF pulse, MXY exponential decay, As shown in Figure 4, When T2=M z (t) =M0e-t/T2, eso es, the transverse relaxation time T2 is the time required to restore M z to 0.63M0. The decay of hydrogen protons in different physical environments is different. Based on certain assumptions, the calculation formulas of the XDL model are obtained, respectivamente, the proportion of the cross-linking chain, the dangling chain and the free chain signal in the total signal.

Higo 3: The magnetization vector weight in the XOY plane attenuate with the right

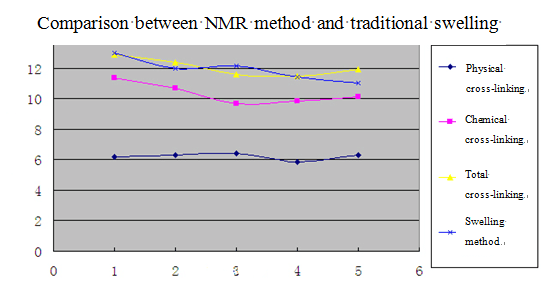

Comparison of the value of cross-linking density between NMR and swelling method:

Higo 4: Comparison between NMR method and traditional swelling

Pictured above is the vulcanized rubber test comparison. The NMR method can obtain the physical cross linking, chemical cross-linking and total cross-linking. Each index reflected the sample different cross-linking state inside, and compared with the swelling method, total cross-linking degree and swelling test results are basically the same. And NMR has very prominent advantages:

Rápido: a single sample only need a few minutes to complete;

Green Initiative:testing process without using any chemical reagent;

Convenient: Sample preparation is simple and without any requirement to the sample form;

Non destructive: same sample can test repeatedly, only need a portrait experiment.

In the field of polymer materials, low field NMR can provide the following research program:

1)Evaluate the cross-linking information of the linked polymer (especially rubber, rubber products)

2) Evaluate the physical property information of the cross-linking polymeric (especially for rubber and rubber products) ;

3) Evaluate the quality of aging process for the used polymer material

4) Study on the optimization of curing, treatment and production conditions based on rubber;

5) Study of the molecular activity of solid, semi hard ,polymer gel, emulsion and liquid;

6) Imaging and determination of moisture and water content in solid media (e.g. epoxy resin and semiconductor equipment);

7) The detection of the vulcanization state, Curing process, viscosity and process for epoxy resin and rubber

8) Study on the adhesion and activity of water or solution in a sample;

9) Determination of plasticizer or rubber content in polymers;

10) Determination of rubber content in blends or copolymers;

11) Determination of relative content of copolymer;

12) Determination of solid content in rubber latex;

13) Study on critical water and hydration;

14) Rheological studies, such as viscosity, densidad, and stability of the material;

mohoso

mohoso