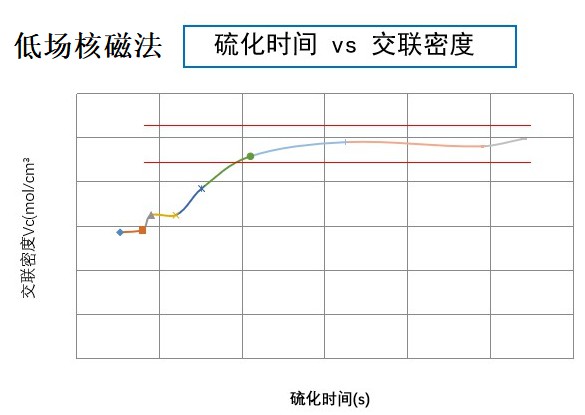

ЯМР во временной области (ядерный магнитный резонанс) представляет собой мощный метод измерения плотности сшивки в резиновых материалах.. Он обеспечивает неразрушающий метод оценки качества и постоянства вулканизации резины.. В данном контексте, Плотность сшивки относится к количеству химических связей, образующихся между полимерными цепями в каучуке во время вулканизации..

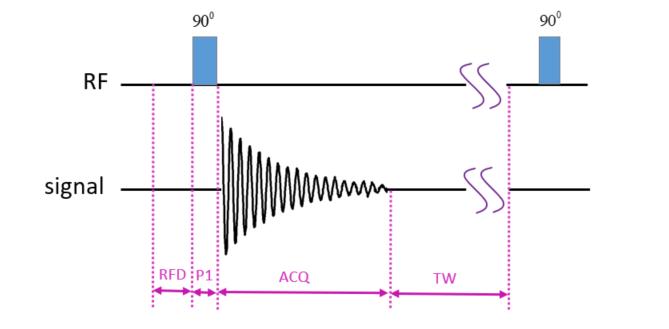

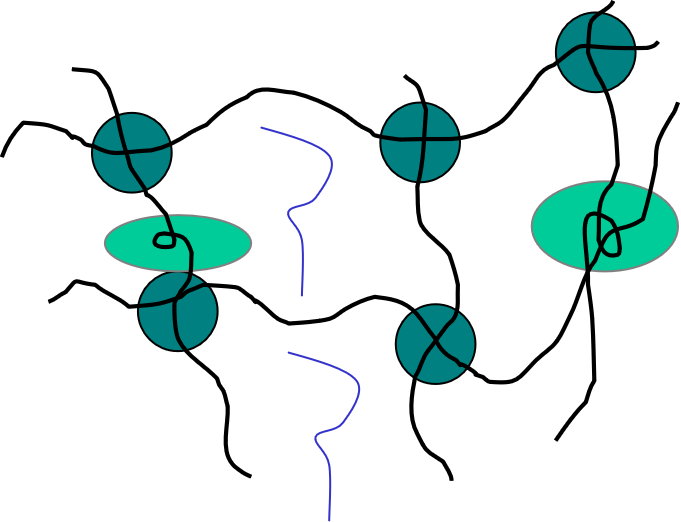

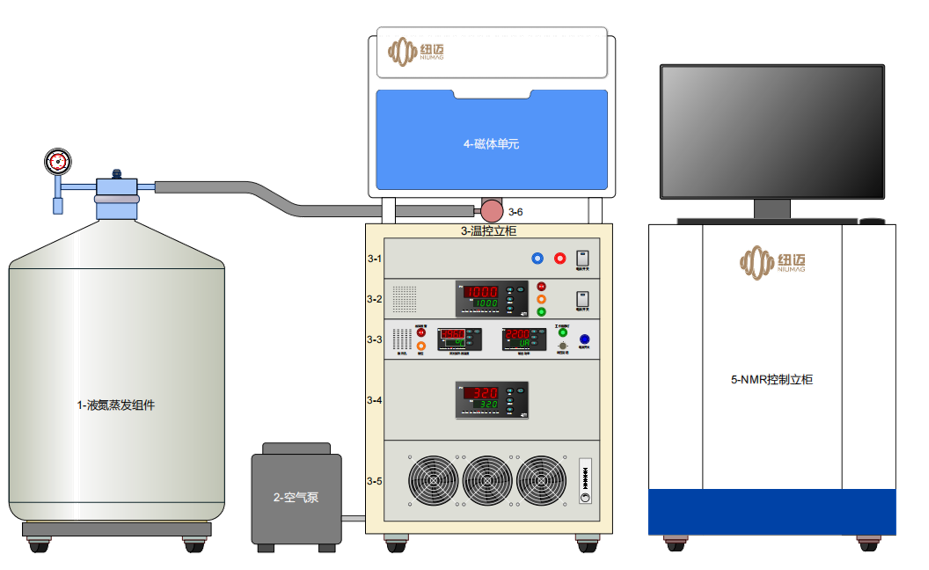

The principle of time-domain NMR for rubber crosslinking density measurement is based on the relaxation behavior of protons in the rubber. When a sample of rubber is placed in a strong magnetic field, the protons align with the field. Pulsed radiofrequency fields are then used to perturb this alignment, exciting the protons into a higher energy state. As the protons relax back to their equilibrium state, a relaxation curve is obtained. The rate of relaxation is directly related to the mobility of the protons, which is influenced by the crosslinking density of the rubber. Crosslinked component has a lower mobility, resulting in a small relaxation rate and a shorter relaxation time.

Time-domain NMR is used to assess the crosslinking density of rubber materials in various applications. One such application is tire manufacturing, where consistent crosslinking density is essential for tire performance and durability. By measuring the relaxation time of the rubber, manufacturers can ensure that the vulcanization process has resulted in optimal crosslinking and that the tire meets quality standards.

Another application is in rubber product testing, where time-domain NMR can be used to evaluate the crosslinking density of rubber hoses, belts, and other industrial products. This information can be used to assess product performance, долговечность, and reliability.

В заключение, time-domain NMR provides a valuable tool for measuring the crosslinking density of rubber materials. It offers a non-destructive method to assess the quality and consistency of vulcanization processes, ensuring that rubber products meet performance requirements in various applications.

заплесневелый

заплесневелый