Introduction:

Rubber products are ubiquitous in our daily lives, known for their excellent performance and user experience. However, rubber aging is a phenomenon that affects the longevity and performance of these products. Understanding the causes and effects of rubber aging is crucial for manufacturers and users alike. This article delves into the role of low-field nuclear magnetic resonance (NMR) technology in studying and assessing rubber aging.

Rubber aging is primarily caused by three factors: high temperatures, chemical influences, and ozone exposure. High temperatures accelerate the oxidation process of rubber materials, leading to degradation. Chemical factors can also expedite the aging process, as rubber is a chemical substance susceptible to certain chemical reactions. Ozone, in particular, can rapidly deteriorate the performance of rubber products.

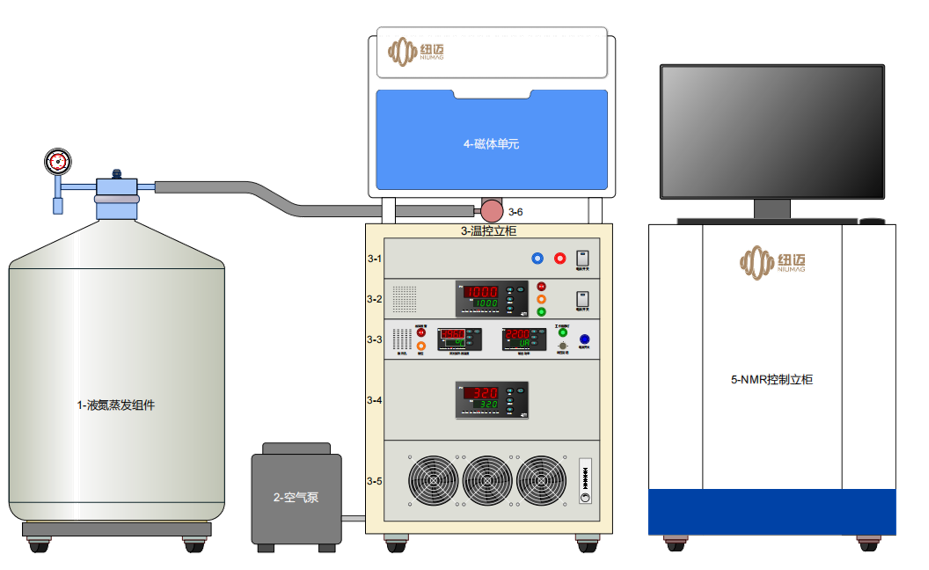

To assess the extent of rubber aging and its impact on product performance, various testing methods are employed. One such method is the low-field NMR technology, which has proven to be highly effective in detecting and analyzing the molecular changes associated with rubber aging.

The fundamental principle of low-field NMR involves measuring the relaxation time of hydrogen protons (1H) in a constant magnetic field. By applying a radiofrequency pulse to the sample within the magnetic field, the hydrogen protons resonate and absorb energy. This energy is then released non-radiatively as the protons return to their baseline state, a process known as relaxation. The relaxation time, which can be categorized into longitudinal and transverse relaxation, is influenced by the physical and chemical environment of the hydrogen protons within the sample.

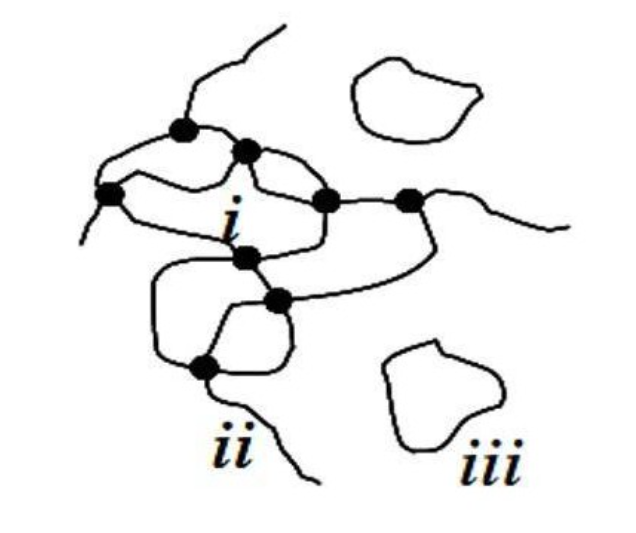

NMR technology is particularly sensitive to changes in the cross-linking system of rubber, which is a comprehensive process during aging. The transverse relaxation time (T2) exhibits a regular pattern of change with the progression of the aging process. By studying these changes and their relationship to the aging properties, one can indirectly evaluate the characteristics of rubber aging.

Low-field NMR technology offers a sophisticated and sensitive method for analyzing rubber aging. It provides valuable insights into the molecular dynamics and structural changes that occur during the aging process. For manufacturers, this technology can be instrumental in improving product quality and extending the service life of rubber products. For users, understanding the aging process can help in making informed decisions regarding the maintenance and replacement of rubber products.

Keywords: Rubber Aging, Low-Field Nuclear Magnetic Resonance, NMR Technology, Rubber Performance, Aging Detection, Molecular Dynamics, Cross-Linking System, Relaxation Time, T2, Product Quality, Service Life.

NIUMAG

NIUMAG