Introduction

Beef is rich in nutrients and perishable and is a common meat in daily diets around the world. Low temperature can inhibit the growth of microbes and enzyme activity in meat, but chilled beef will inevitably deteriorate during manufacturing, transportation and storage, resulting in deterioration of beef quality, such as taste, color and other physical and chemical changes. Therefore, it is necessary to assess the quality of beef during refrigeration.

Traditional physical and chemical methods are susceptible to subjective and environmental factors and have poor repeatability. Low-field NMR(LF-NMR) technology has been widely used as a fast and non-destructive detection method to study the state and distribution of moisture in food.

LF-NMR relaxation parameters combined with chemometrics methods have successfully achieved prediction of moisture content, fat, quality parameters, etc. in fresh beef samples. However, there are few studies on the changes and distribution of moisture status of beef during cold storage and its relationship with other quality indicators.

Results

LF-NMR relaxation analysis

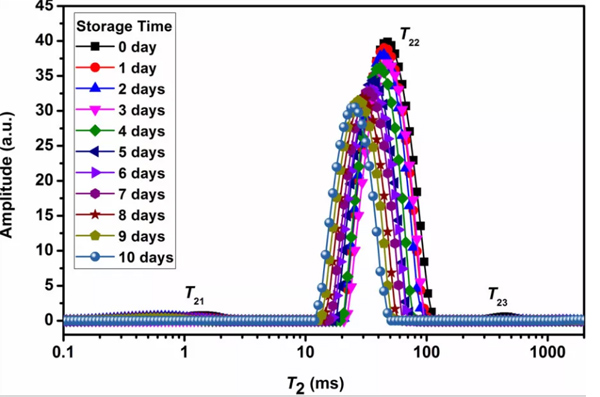

LF-NMR T2 distribution fitting curve can be used to evaluate different moisture status in beef. Figure 1 shows the T2 transverse relaxation time of beef stored at 4 ° C for different times, where each curve represents the average of 18 measurements. It can be seen from the figure that there are three relaxation peaks in the beef sample. The relaxation time of the first peak is the shortest, between 0.1-10 ms (T21), representing water tightly attached to the polar groups of macromolecules, such as proteins on the water. The second peak is the largest, between 10-100 ms (T22), which represents the hard-to-flow water fixed in the internal network structure of myofibrils, and its signal reaches more than 90% of the entire signal value. The relaxation time of the third peak is between 100-1000 ms (T23), representing free water between myofibrils.

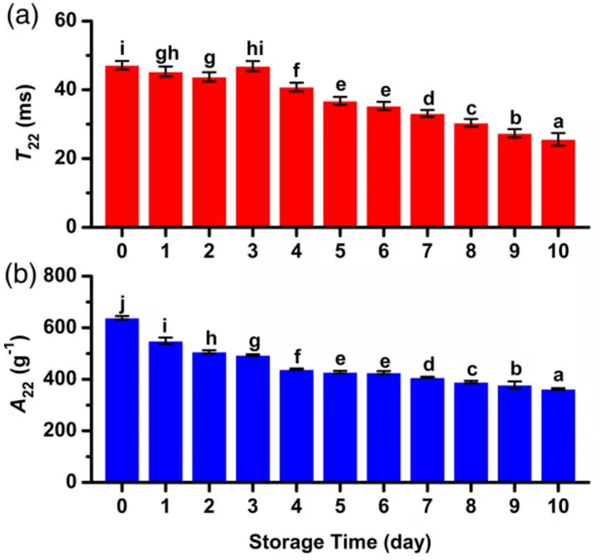

It can be seen from the figure that the hard-to-flow water is the main moisture of beef, and the change is most obvious during the storage of beef. The changes of relaxation time and peak area with storage time are shown in Figure 2.

It can be seen from Fig. 2 that as the storage time increases, the relaxation time and peak area of the hard-to-flow water show a downward trend, indicating that their fluidity and moisture content both decreases. The reduction in relaxation time can be attributed to the contraction of beef myofibrillars during storage, the increased strain in the myofibrils, and the retention of water in the myofibers or diffusion into the interstitium. The decrease in relaxation peak area can be attributed to the migration of water inside the myofibrils to the outside of the cells.

MRI Analysis

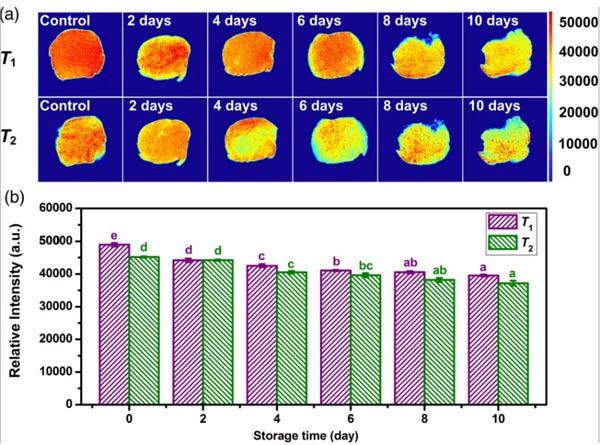

T1 and T2 weighted imaging were used to study the moisture distribution of beef samples during storage at 4 ° C. The pseudo-color image in Figure 3 (a) shows that the brightness of the fresh sample (day 0) is dense and uniform. With the extension of storage time, the brightness of the beef surface decreased first, and then the internal brightness both decreased, indicating that the moisture content of beef muscle decreased, which may be due to the degradation and denaturation of muscle protein during storage, resulting in a part of the difficult flowing water into free water , Free water gradually penetrates to the surface. Figure 3 (b) Quantitative signal intensity results show that with the extension of storage time, the gray values of T1 and T2 images both decreased significantly.

Conclusion

During the cold storage of beef, the lateral relaxation time and peak area of hard-to-flow water were significantly reduced. The change of microstructure caused by the deterioration may be the main reason for the decrease of water mobility, water content and water holding capacity. LF-NMR can identify beef samples with different storage time.

The results show that LF-NMR can replace traditional physical and chemical methods to evaluate beef quality as a fast and nondestructive detection method.

Reference:

ShashaCheng,XiaohuiWang,HuiminYang.Characterizationof moisture migration of beef during refrigeration storage by low-field NMR andits relationship to beef quality. Food Agric(2020 )

NIUMAG

NIUMAG